nuevo blog

En los últimos años, PP modificado con fibra de vidrio larga es extremadamente popular en la industria del plástico modificado. Material PP reforzado con fibra de vidrio larga El precio es bajo, tiene un rendimiento excelente no menos que los plásticos de ingeniería reforzados; En conjunto, estos dos puntos muestran la ventaja del rendimiento de alto costo, por lo que la industria es ampliamente optimista. En la actualidad, estos fabricantes han invertido mucha mano de obra y recursos materiales en la producción y desarrollo de este tipo de material y desarrollo del mercado.

Entonces, ¿qué es el PP modificado con fibra de vidrio larga?

Material PP

Como uno de los materiales plásticos generales, el PP tiene un rendimiento integral excelente, buena estabilidad química, mejor rendimiento de moldeo y un precio relativamente bajo. Pero el PP tiene baja resistencia, módulo, dureza, resistencia al impacto a baja temperatura, contracción de formación, fácil envejecimiento y otras deficiencias.

En términos generales, la resistencia a la tracción del material PP está entre 20~30MPa, la resistencia a la flexión está entre 25~50MPa y el módulo de flexión está entre 800~1500MPa. Por ello, se modifica para adaptarse a las necesidades de los productos. Hoy en día, cada tipo de PP modificado tiene un gran número de aplicaciones en el campo de los electrodomésticos y los vehículos.

Fibra de vidrio larga

La fibra de vidrio es un tipo de material inorgánico no metálico con excelente rendimiento. Las ventajas son un buen aislamiento, una fuerte resistencia al calor, una buena resistencia a la corrosión y una alta resistencia mecánica, pero las desventajas son la fragilidad y la escasa resistencia al desgaste. Uno de los principales usos de la fibra de vidrio es reforzar materiales compuestos.

Fibra de vidrio larga generalmente se refiere a una longitud de fibra de vidrio de más de 10 mm.

Plásticos PP reforzados con fibra de vidrio larga

El plástico PP reforzado con fibra de vidrio larga se refiere al material compuesto de PP modificado que contiene una longitud de fibra de vidrio de 10 a 25 mm, después del moldeo por inyección y otros procesos para formar una estructura tridimensional de fibra de vidrio con una longitud superior a 3,1 mm, abreviada como LGF-PP. Muchos materiales en el país y en el extranjero se refieren al termoplástico reforzado con fibra larga como LFT (es decir, termoplástico reforzado con fibra larga). Según la definición del material, LGFPP pertenece a un tipo de LFT.

Como material portador de módulos de vehículos, el material no solo puede mejorar eficazmente la rigidez, la resistencia al impacto, la resistencia a la fluencia y la estabilidad dimensional del producto, sino que también puede fabricar productos complejos de módulos de vehículos.

Generalmente 12 mm o 25 mm de longitud, diámetro de aproximadamente 3 mm de partículas columnares. La longitud del grano de aproximadamente 12 mm se usa principalmente para moldeo por inyección, y la longitud de aproximadamente 25 mm del grano se usa principalmente para moldeo por presión. En esta partícula, la fibra de vidrio tiene la misma longitud que la partícula, el contenido de fibra de vidrio puede variar del 20 al 70 por ciento y el color de la partícula puede combinarse según los requisitos del cliente.

¿Por qué Ford utiliza PP reforzado con fibra de vidrio larga en lugar de PP reforzado con fibra de vidrio corta?

Para mejorar la resistencia de la fibra de vidrio en los plásticos, la longitud de la fibra de vidrio debe ser mayor que su longitud crítica Lo. Los datos relevantes muestran que cuando la longitud de la fibra es menor que la longitud crítica del plástico reforzado con fibra sometido a una determinada carga, la fibra se arrancará y la resistencia de la fibra no podrá alcanzar su máximo rendimiento. La longitud crítica Lo es específica de la variedad de plástico. En el caso del polipropileno reforzado con fibra de vidrio, el Lo es de 3,1 mm.

Los resultados muestran que el modo de falla es principalmente que la fibra se arranca y no puede cumplir con el requisito de resistencia del material portador del módulo. Por lo tanto, el desarrollo y aplicación del polipropileno reforzado con fibra de vidrio larga y su tecnología de moldeo por inyección, es preparar la longitud de fibra de vidrio reforzada de materias primas de polipropileno de aproximadamente 10 mm y, a través del proceso de moldeo por inyección mejorado, garantizar que la longitud de la fibra de vidrio en el el producto mide más de 3,1 mm.

Ventajas de LFT en comparación con compuestos termoplásticos reforzados con fibra corta:

Las propiedades mecánicas del producto obviamente mejoran gracias a la mayor longitud de la fibra.

Alta rigidez y resistencia específicas, buena resistencia al impacto, especialmente adecuado para aplicaciones automotrices.

Se mejora la resistencia a la fluencia, la estabilidad dimensional es buena y la precisión de formación de las piezas es alta.

Excelente resistencia a la fatiga.

Mejor estabilidad en ambientes cálidos y húmedos.

La fibra puede moverse relativamente en el molde de moldeo durante el proceso de moldeo y el daño a la fibra es pequeño.

Proceso de fabricación de PP reforzado con fibra de vidrio larga

Hay tres procesos de producción: GMT, LDT-G y LDT-D

Aplicación de PP reforzado con fibra de vidrio larga

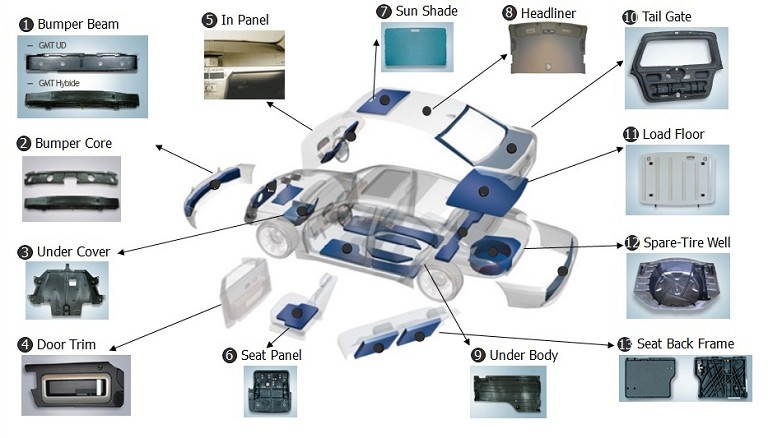

Industria del automóvil: módulo frontal, módulo de puerta, mecanismo de cambio, pedal de acelerador electrónico, esqueleto del tablero, marco y ventilador de refrigeración, soporte de batería, soporte de parachoques, placa de protección de los bajos, marco del techo corredizo, etc., que se utilizan para reemplazar el PA reforzado o materiales metálicos.

Industria de electrodomésticos: tambor de lavadora, soporte triangular de lavadora, tambor de una máquina de cepillo, ventilador de aire acondicionado, etc., que se utilizan para reemplazar materiales metálicos o PA, ABS o PA reforzados con fibra de vidrio corta.

Industria de comunicaciones, electrónica y electrodomésticos: conectores de alta precisión, componentes de encendedor, eje de bobina, base de relé, marco/marco de bobina de transformador de horno microondas, conector eléctrico, paquete de válvula solenoide, componentes de escáner, etc.

Otros: carcasas de herramientas eléctricas, carcasas de bombas o medidores de agua, impulsores, esqueleto de bicicletas, esquís, pedales de locomotoras terrestres, cascos de seguridad militar/civil, zapatos de seguridad, etc., utilizados para reemplazar PA, PPO, reforzados con fibra de vidrio corta. etc.

Sobre nosotros

Xiamen LFT composite plastic Co., Ltd es una empresa de marca que se centra en LFT y LFRT. Serie de fibra de vidrio larga (LGF) y serie de fibra de carbono larga (LCF). El termoplástico LFT de la empresa se puede utilizar para moldeo por inyección y extrusión LFT-G, y también para moldeo LFT-D. Se puede producir según los requisitos del cliente: 5 ~ 25 mm de longitud. Los termoplásticos reforzados con infiltración continua de fibra larga de la empresa han pasado la certificación del sistema ISO9001 y 16949, y los productos han obtenido muchas marcas comerciales y patentes nacionales.