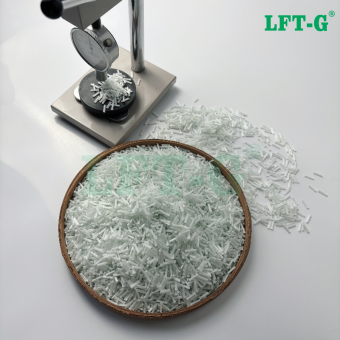

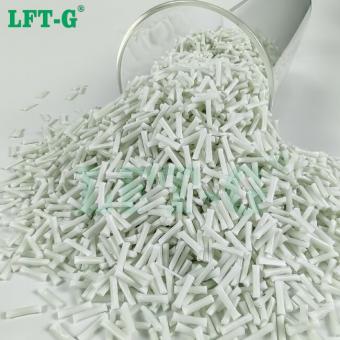

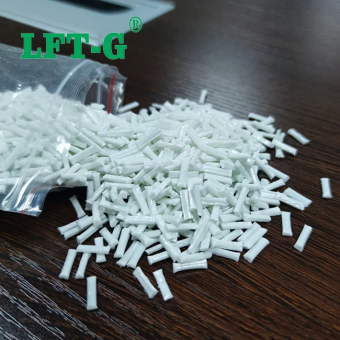

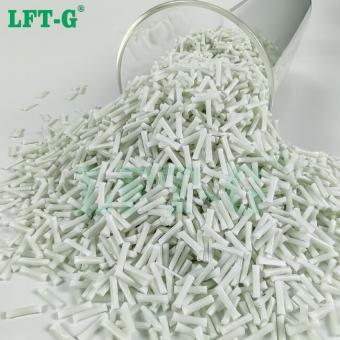

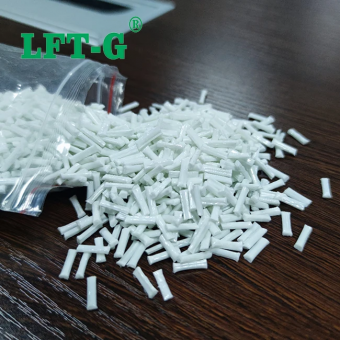

La fibra de vidrio larga tiene alta resistencia, alta rigidez, resistencia a la corrosión, idoneidad para ambientes hostiles y bajo costo. cuando la matriz de resina se impregna y se extruye en gránulos, también se llama polímero de fibra de vidrio largo Tiene buenas propiedades mecánicas.

-

Pellets compuestos de poliamida MXD6 con un contenido de fibra de vidrio larga del 20 al 60 %MXD6 es una poliamida semiaromática de alto rendimiento conocida por su excepcional l Propiedades de barrera de gas, resistencia mecánica y estabilidad térmica Se utiliza ampliamente en Aplicaciones automotrices, de embalaje e industriales donde la durabilidad y la resistencia química son esenciales. Ideal para componentes estructurales y funcionales MXD6 ofrece un rendimiento confiable en entornos exigentes.ver más

-

Moldeo por inyección de gránulos de resina de PE de alta densidad reforzados con fibra de vidrioEste material combina polietileno de alta densidad (HDPE) con fibras de vidrio largas Para mayor resistencia mecánica, resistencia al impacto y estabilidad dimensional. Es ideal para aplicaciones estructurales que requieren durabilidad, ligereza y resistencia química, y se utiliza comúnmente en productos automotrices, industriales y de exterior.

- tubería compuesta de HDPE reforzada con fibra

- vidrio de HDPE

- soluciones de reemplazo de metales

- materiales compuestos termoplásticos

- pellets lft

- compuestos de fibras largas

Etiquetas :

-

Moldeo por inyección de gránulos de resina PLA reforzada con fibra de vidrioPLA en sí mismo es un respetuoso con el medio ambiente termoplástico, conocido por su biodegradabilidad Sin embargo, tiene propiedades mecánicas limitadas, como resistencia, tenacidad y resistencia al calor. Al incorporar fibras de vidrio largas , el rendimiento del PLA mejora significativamente, lo que lo hace adecuado para exigentes aplicaciones.

- plástico pps

- soluciones compuestas termoplásticas de fibra larga

- bolitas de plástico pla

- compuesto de fibra de vidrio termoplástica

- PRFV termoplástico

Etiquetas :

-

Moldeo por inyección de gránulos de resina ABS reforzada con fibra de vidrioDespués añadiendo fibra de vidrio al ABS , la rigidez, resistencia al calor y estabilidad dimensional Los resultados del compuesto se han mejorado significativamente. Además, la relación calidad-precio del ABS con fibra de vidrio es extremadamente buena, lo que satisface las necesidades de los fabricantes. reduciendo costos .

- punto de fusión del plástico ABS

- bolitas de plástico ABS

- fabricante de gránulos de ABS

- color abdominales naturales

- compuesto de fibra de vidrio ABS

- materia prima de ABS

Etiquetas :

-

Moldeo por inyección de plástico de fibra de vidrio larga PBT de excelente rigidezAdición de fibra de vidrio al PBT Es un método común para mejorar y modificar el PBT. La fuerza de adhesión entre la fibra de vidrio y la resina PBT es buena. Tras añadir cierta cantidad de fibra de vidrio a la resina PBT, no solo se conservan las ventajas originales de la resina PBT, como la resistencia química y la procesabilidad, sino que también... mejorar sus propiedades mecánicas y superar los problemas. Sensibilidad de muesca de resina PBT.

- hoja de datos de pbt

- polímero PBT

- propiedades del pbt

- compuesto de PBT

- usos de pbt

- proveedores de PBT

Etiquetas :

-

Moldeo por inyección de gránulos de resina PLA reforzada con fibra de vidrioEPL en sí mismo es un respetuoso con el medio ambiente termoplástico, conocido por su biodegradabilidad Sin embargo, tiene propiedades mecánicas limitadas, como resistencia, tenacidad y resistencia al calor. Al incorporar fibras de vidrio largas , el rendimiento del PLA se mejora significativamente, lo que lo hace adecuado para demandante aplicaciones.ver más

-

Plásticos de ingeniería personalizados de fibra de vidrio larga compuesta LGF de sulfuro de polifenileno LFT-G PPSPPS y PPS-LGF | Plástico de ingeniería de alto rendimiento ¿Qué es PPS? El sulfuro de polifenileno (PPS) es un termoplástico de ingeniería de alto rendimiento, conocido por su excelente resistencia térmica, estabilidad química, resistencia al fuego y resistencia mecánica. Mediante refuerzo y modificación, el PPS ofrece una combinación equilibrada de propiedades físicas, mecánicas y eléctricas. El PPS presenta una excelente estabilidad dimensional, resistencia a la corrosión y rendimiento de aislamiento eléctrico, lo que lo hace adecuado para entornos industriales hostiles. Características clave del PPS Excelente resistencia a altas temperaturas. Alta dureza y resistencia al desgaste. Fuerte resistencia a la fluencia bajo carga a largo plazo Excelentes propiedades eléctricas en un amplio rango de temperaturas. Baja sensibilidad de las propiedades mecánicas a los cambios de temperatura. El PPS sin modificar es frágil por naturaleza y presenta una resistencia al impacto relativamente baja. Estas limitaciones pueden superarse eficazmente mediante el refuerzo de fibras y la modificación del material. ¿Qué es PPS-LGF? PPS-LGF se refiere al sulfuro de polifenileno reforzado con fibra de vidrio larga. Entre los plásticos de ingeniería, el PPS-LGF destaca por su excelente resistencia térmica, resistencia estructural y fiabilidad a largo plazo. Temperatura de deflexión térmica (HDT) superior 260°C Resistencia química sólo superada por el PTFE Baja contracción de moldeo y absorción de agua extremadamente baja. Excelente resistencia al fuego y a la fatiga por vibración. Excelente aislamiento eléctrico incluso en entornos de alta humedad y alta temperatura. Al incorporar fibras de vidrio largas, PPS-LGF mejora significativamente la tenacidad y la resistencia al impacto, superando la fragilidad del PPS puro y brindando un excelente rendimiento integral. En muchas aplicaciones, PPS-LGF puede reemplazar metales como acero inoxidable, cobre, aluminio y aleaciones, lo que lo convierte en un material ideal para el reemplazo de metales y el diseño liviano. Marcador de posición de imagen Aplicaciones de PPS-LGF El PPS-LGF se utiliza ampliamente en industrias que requieren alta resistencia, resistencia al calor y estabilidad química, entre las que se incluyen: Componentes automotrices Estructuras aeroespaciales Electrodomésticos Piezas mecánicas y estructurales Equipos de procesamiento químico Aislamiento eléctrico y componentes resistentes a la corrosión Detalles del producto Calificación Color Longitud del perdigón Cantidad mínima de pedido Embalaje Muestra El tiempo de entrega Puerto de carga PPS-NA-LGF30 Natural (personalizable) ≥ 5–25 mm 25 kilos 25 kg / bolsa Disponible 7–15 días después del envío Puerto de Xiamen Proceso de producción Nuestros materiales PPS-LGF se producen utilizando tecnología avanzada de impregnación de fibra larga, lo que garantiza una excelente retención de la longitud de la fibra, una dispersión uniforme y un rendimiento mecánico estable. Marcas y patentes Nuestros materiales están respaldados por tecnologías patentadas, marcas registradas y procesos patentados para garantizar una calidad constante y un rendimiento confiable. Equipos y clientes Con el respaldo de un experimentado equipo de I+D y producción, nuestros materiales PPS-LGF cuentan con la confianza de clientes de todo el mundo en los sectores automotriz, industrial y eléctrico. Lo que ofrecemos Datos técnicos de materiales LFT y LFRT y soporte de diseño avanzado Recomendaciones y optimización del diseño del frente del molde Soporte técnico profesional para el procesamiento de moldeo por inyección y extrusión.

- PPS Fibra de vidrio larga 40

- compuestos de pps lgf

- materiales de resina pps lft

- plástico reforzado con pps lft-g

- relleno de fibra de vidrio larga pps

- resina termoplástica pps lgf

Etiquetas :

-

Compuestos termoplásticos reforzados con fibra de vidrio larga (ABS) Xiamen LFTDescripción general del ABS-LGF (ABS reforzado con fibra de vidrio) El ABS es un plástico de ingeniería versátil, conocido por su estabilidad química y térmica, resistencia, dureza y acabado brillante. Se utiliza ampliamente en productos de consumo como juguetes y cascos, así como en aplicaciones automotrices como revestimientos interiores, carcasas para dispositivos electrónicos y más. El refuerzo del ABS con fibra de vidrio mejora significativamente la rigidez, la resistencia térmica y la estabilidad dimensional. Los compuestos ABS-LGF ofrecen una excelente relación calidad-precio, lo que ayuda a los fabricantes a reducir costes y a satisfacer las necesidades de producción. Acerca de los compuestos ABS-LGF Aplicaciones del ABS modificado 1. Piezas de automoción: Paneles de instrumentos, guardabarros, interiores, luces, espejos, sistemas de audio. 2. Componentes electrónicos y eléctricos: Carcasas de equipos de TI y OA, convertidores, tomas de corriente. 3. Electrodomésticos: Interruptores, controladores, monitores, carcasas, soportes. 4. Electrodomésticos: Componentes eléctricos, cajas de control. Ventajas del moldeo por inyección de ABS Alta productividad: Proceso eficiente y con bajos residuos, ideal para fabricación de grandes volúmenes. Diseño de piezas complejas: Capaz de realizar componentes con múltiples funciones, incluidos sobremoldeo e inserciones de metal. Mayor fuerza: El ABS proporciona una excelente resistencia mecánica y durabilidad. Opciones flexibles de colores y materiales: Se puede colorear, pintar o galvanizar fácilmente para mejorar la resistencia ambiental. Reducción de residuos: Producción con bajo desperdicio, limitada a bebederos, canales y tapajuntas. Bajo costo de mano de obra: El proceso altamente automatizado reduce la intervención humana y disminuye el coste por pieza. Detalles del material Número ABS-NA-LGF Color Natural o personalizado Longitud 6-25 milímetros Paquete 25 kg/bolsa Cantidad mínima de pedido 25 kilos Plazo de entrega 2-15 días Puerto de carga Puerto de Xiamen Términos comerciales EXW/FOB/CFR/CIF/DDU/DDP Acerca de Xiamen LFT Fundada en 2009, Xiamen LFT Composite Plastics Co., Ltd. es un proveedor líder mundial de materiales termoplásticos reforzados con fibra larga, que integra I+D, producción y comercialización. Nuestros productos cuentan con las certificaciones ISO9001 e IATF16949, están patentados y se utilizan en los sectores automotriz, aeroespacial, médico, de nuevas energías, militar, de equipamiento deportivo y más. En comparación con los termoplásticos de fibra corta (fibras de 1-2 mm), nuestros materiales LFT (fibras de 5-25 mm) están completamente impregnados de resina, lo que garantiza un rendimiento mecánico superior. Las resinas base incluyen PP, PA6, PA66, PPA, PA12, MXD6, PBT, TPU, PPS, ABS, PEEK, etc. Las fibras convencionales incluyen fibra de vidrio y carbono. Los productos terminados pueden utilizarse para moldeo por inyección, extrusión o sustituir directamente componentes de acero y termoestables.

- Plásticos termoplásticos de ingeniería de alto rendimiento

- Excelente resistencia al calor con relleno.

- Productos de moldeo por inyección ligeros

- Piezas de automóviles y electrodomésticos

- El fabricante de plástico modificado se puede personalizar

- Se puede reciclar GFRP GF30

Etiquetas :

-

Compuesto de nailon PA12 de alta resistencia LGF, color blanco virgen para automoción.Número de producto: PA12-NA-LGF Especificación de la fibra: 20%-60% Característica del producto: Alta resistencia, alta tenacidad y durabilidad. Aplicación del producto: Adecuado para automoción, piezas deportivas, energía solar, industria fotovoltaica y otras industrias.

- Relleno de nailon 12, plástico reforzado con fibra de vidrio larga

- Alta durabilidad y propiedades mecánicas.

- Compuestos de la industria fotovoltaica

- Resina termoplástica de grado inyectable

- Servicio 24h de plástico personalizado en lugar de metal.

- Precio de proveedor buen precio compuestos pa6

Etiquetas :

-

Resina termoplástica reforzada con fibra de vidrio larga de poliamida 66 serie nailonLa poliamida, también conocida como nailon, posee excelentes propiedades de resistencia al calor, especialmente al combinarse con aditivos y materiales de relleno. Además, el nailon es muy resistente a la abrasión. Xiamen LFT ofrece una amplia gama de nailones resistentes a la temperatura con diversos materiales de relleno. Acerca de los compuestos PA66-LGF El nailon 6,6, también conocido como nailon 6-6, nailon 66 o nailon 6/6, es una versión más cristalina del nailon 6. También se le conoce como poliamida 66 o PA 66. Presenta propiedades mecánicas mejoradas gracias a su estructura molecular más ordenada. El nailon 66 para mecanizado presenta una mayor resistencia a la temperatura y una menor absorción de agua en comparación con el nailon 6 estándar. Las ventajas del nailon 6,6 son su mayor límite elástico que el nailon 6 y el nailon 610. Presenta alta resistencia, tenacidad, rigidez y bajo coeficiente de fricción en un amplio rango de temperaturas. Además, es resistente al aceite, a reactivos químicos y a disolventes. Sin embargo, el PA66 presenta una alta higroscopicidad y una baja estabilidad dimensional, lo que limita su aplicación. Para obtener un material de ingeniería de nailon 66 con mayor resistencia, es necesario modificarlo con un refuerzo de fibra de vidrio. Las propiedades mecánicas del nailon 66 reforzado con fibra de vidrio larga (LGFR-PA66) son claramente superiores a las del nailon 66 reforzado con fibra de vidrio corta (SGFR-PA66), y su rendimiento de moldeo también es superior. Puede moldearse mediante diversos métodos, como el moldeo por inyección y el moldeo por compresión, y también permite formar componentes complejos. Por lo tanto, el nailon 66 reforzado con fibra de vidrio larga se puede utilizar ampliamente en materiales de construcción, aeroespacial, dispositivos electrónicos, muebles y otros campos, especialmente en el mercado de aplicaciones de la industria automotriz. El proceso de producción del nailon 66 reforzado con fibra de vidrio larga es diferente al del nailon 66 reforzado con fibra de vidrio corta. Las partículas cortas de nailon 66 reforzado con fibra de vidrio se trituran bajo la fricción y el cizallamiento del tornillo y el cilindro, obteniéndose una longitud de monofilamento de fibra de vidrio de aproximadamente 0,5 mm. La longitud de algunos monofilamentos de fibra de vidrio en el producto final es inferior a la longitud crítica del refuerzo, y la fibra de vidrio se desprende fácilmente de la matriz de nailon 66 cuando el producto se somete a tensión. La resistencia de la fibra de vidrio no se aprovecha al máximo y las propiedades mecánicas del producto son deficientes. El nailon 66 reforzado con fibra de vidrio larga tiene un mejor efecto de refuerzo y estabilidad dimensional, y la rigidez, la tracción, la flexión, la resistencia al impacto y la resistencia a la fatiga de los productos fabricados son mejores y la vida útil es más larga. Detalles de los materiales Número ber PA66-NA-LGF Colo o Color natural o personalizado Len gth 6-25 metros metro Pac kage 25 kg/bolsa mes Q 25 kilos L cabeza tiempo 2-15 días Puerto de Cargando gramo Puerto de Xiamen Tr ade te RMS EXW/ FOB/CFR/CIF/DDU/DDP Acerca de Xiam en Prueba de función hepática Xiamen LFT Composite Plastic Co., LTD., fundada en 2009, es un proveedor global de renombre de materiales termoplásticos reforzados con fibra larga que integra investigación y desarrollo (I+D), producción y comercialización de productos. Nuestros productos LFT cuentan con las certificaciones ISO 9001 y 16949 y cuentan con numerosas marcas y patentes nacionales, en los sectores de la automoción, piezas militares y armas de fuego, aeroespacial, nuevas energías, equipos médicos, energía eólica, equipos deportivos, etc. Los materiales termoplásticos de ingeniería reforzados con fibra larga LFT, en comparación con los materiales termoplásticos reforzados con fibra corta ordinarios (longitud de fibra inferior a 1-2 mm), el proceso LFT produce fibras de material termoplástico de ingeniería en longitudes de 5-25 mm. Las fibras largas se impregnan con la resina a través de un sistema de moldeo especial para obtener tiras largas que están completamente impregnadas con la resina, y luego se cortan a la longitud necesaria. La resina base más utilizada es PP, seguida de PA6, PA66, PPA, PA12, MXD6, PBT, TPU, PPS, ABS, PEEK, etc. Las fibras convencionales incluyen fibra de vidrio y fibra de carbono. Dependiendo del uso final, los productos terminados pueden utilizarse para moldeo por inyección, extrusión, moldeo, etc., o usarse directamente para plástico en lugar de acero y productos termoestables.ver más

-

Xiamen LFT-G Nylon 6 Poliamida 6 compuesto Fibra de vidrio larga plástico modificado 12 mm color originalDescripción general del material PA6 La PA6 (poliamida 6) es un plástico de ingeniería ampliamente utilizado con un rendimiento excelente y equilibrado. Sus materias primas son fáciles de conseguir y rentables, lo que facilita su acceso sin depender de tecnología extranjera. Sin embargo, la PA6 presenta algunas limitaciones, como una alta absorción de agua, una menor tenacidad al impacto a baja temperatura y una estabilidad dimensional moderada. Para superar estas limitaciones, la PA6 suele reforzarse con fibra de vidrio (FV) para mejorar sus propiedades mecánicas. PA6-LGF (PA6 reforzado con fibra de vidrio larga) 1. Influencia del contenido de fibra de vidrio El contenido de fibra de vidrio es un factor clave en el rendimiento de los compuestos reforzados. Un mayor contenido de fibra aumenta su densidad, reduciendo la matriz de PA6 entre las fibras. Esto mejora la tenacidad al impacto, la resistencia a la tracción y la resistencia a la flexión. Ejemplo: Para PA6-LGF, aumentar el contenido de fibra al 35 % elevó la resistencia al impacto por entalla de 24,8 J/m a 128,5 J/m. Sin embargo, un contenido excesivo de fibra puede reducir la resistencia al impacto. La resistencia a la flexión también mejora, ya que las fibras transfieren la tensión y absorben energía al romperse. Los resultados experimentales muestran un módulo de flexión de hasta 4,99 GPa para un 35 % de LGF. 2. Influencia de la longitud de retención de la fibra La longitud de la fibra afecta significativamente las propiedades mecánicas. Cuando la longitud de la fibra es inferior a la longitud crítica, aumentarla mejora la unión resina-fibra y la resistencia a la tracción. Cuando la fibra supera la longitud crítica, las fibras más largas absorben más energía de impacto y mejoran la resistencia al impacto, ya que disminuye el número de extremos de fibra (puntos de inicio de grietas). Ejemplo: Con un contenido de fibra del 40 %, al aumentar la longitud de la fibra de 4 mm a 13 mm, la resistencia a la tracción mejoró de 154,8 MPa a 164,4 MPa, con un aumento de la resistencia a la flexión y la resistencia al impacto con entalla en un 24 % y un 28 %, respectivamente. Las fibras de más de 7 mm de longitud mejoran la resistencia a la deformación y la estabilidad mecánica a altas temperaturas y humedad. Referencia de datos técnicos (TDS) El PA6-LGF puede reforzarse con un 20%-60% de fibra de vidrio larga, según los requisitos del producto. En comparación con el PA6 sin reforzar, el PA6-LGF ofrece mayor resistencia, resistencia al calor y al impacto, estabilidad dimensional y menor deformación. La siguiente ficha técnica muestra los datos del PA6-LGF30. Aplicaciones de PA6-LGF PA6-LGF se usa ampliamente en piezas automotrices, electrónicas/eléctricas y de maquinaria/ingeniería. Piezas de automoción Las tendencias de ligereza y miniaturización promueven el uso de PA6-LGF en motores, sistemas eléctricos y componentes de la carrocería. Componentes electrónicos y eléctricos Su excelente resistencia al fuego y a la corrosión hacen que el PA6-LGF sea adecuado para cuadros de distribución, disyuntores, contactores, conectores y tubos de protección de cables. Piezas mecánicas y de ingeniería Su buena resistencia al impacto, al desgaste y sus propiedades de autolubricación permiten que el PA6-LGF se utilice en maquinaria y accesorios de ingeniería. Acerca de Xiamen LFT Composite Plastics Co., Ltd. Xiamen LFT se centra en termoplásticos reforzados con fibra de vidrio larga (LGF) y fibra de carbono larga (LCF). Nuestros materiales LFT son compatibles con el moldeo por inyección (LFT-G) y el moldeo por extrusión, así como con el moldeo LFT-D, con longitudes de fibra de 5 a 25 mm. Nuestros productos cuentan con las certificaciones ISO9001 e IATF16949, están patentados y son ampliamente utilizados en aplicaciones automotrices, electrónicas, industriales y de ingeniería.

- Materiales de resina termoplástica PA6

- gránulos de nailon 6

- gránulos de plástico reforzado con fibra de vidrio

- compuestos de fibra larga pa6

- Moldeo por inyección de plástico

- Material reforzado LFT-G

Etiquetas :

-

Gránulos compuestos de fibra de vidrio larga de plástico de ingeniería de polipropileno Xiamen LFT PP de 12 mm¿Qué es la fibra de vidrio larga (LGF)? Los plásticos reforzados con fibra de vidrio larga (LFT) son materiales de ingeniería que incorporan fibras de vidrio largas y aditivos a un termoplástico base. Esto mejora significativamente la resistencia mecánica, la resistencia térmica, la estabilidad dimensional y el rendimiento general del material. ¿Por qué reforzar con fibra de vidrio larga? Alta resistencia al calor: LFT aumenta significativamente el rendimiento térmico, especialmente para plásticos a base de nailon. Contracción reducida y mayor rigidez: el refuerzo de fibra restringe el movimiento de la cadena de polímero, lo que mejora la estabilidad dimensional y la rigidez. Resistencia al impacto mejorada: los plásticos reforzados son menos propensos al agrietamiento por tensión y tienen mejor tenacidad. Alta resistencia: Las fibras de vidrio largas aumentan la resistencia a la tracción, a la compresión y a la flexión. Retardancia de llama: la mayoría de los materiales LFT son autoextinguibles debido a los aditivos y al contenido de fibra. ¿Por qué elegir fibra de vidrio larga en lugar de fibra de vidrio corta? Una mayor longitud de fibra mejora significativamente las propiedades mecánicas. Alta rigidez y resistencia específicas con excelente resistencia al impacto, ideal para aplicaciones automotrices. Resistencia superior a la fluencia y estabilidad dimensional para piezas de precisión. Excelente resistencia a la fatiga para componentes de larga duración. Estabilidad mejorada en ambientes cálidos y húmedos. Daño mínimo a las fibras durante el moldeo debido al movimiento relativo de las fibras en el molde. Apariencia de PP-LGF Aplicaciones de PP-LGF Piezas de automoción Módulos frontales, módulos de puertas, mecanismos de cambio, pedales de acelerador electrónicos, tableros, ventiladores de refrigeración, soportes de batería, soportes de parachoques, placas de protección de bajos, marcos de techo solar, etc., reemplazando componentes reforzados de PA o metal. Electrodomésticos Tambores de lavadoras, soportes, ventiladores de aire acondicionado, etc. – sustitución de componentes cortos de PA reforzados con fibra de vidrio y de metal. Comunicaciones, Electrónica, Electrodomésticos Conectores de alta precisión, componentes de encendedor, ejes de bobinas, bases de relés, marcos de transformadores de microondas, carcasas de válvulas solenoides, componentes de escáner, etc. Otras aplicaciones Carcasas de herramientas eléctricas, carcasas de bombas/medidores de agua, impulsores, cuadros de bicicletas, esquís, pedales de locomotoras, cascos de seguridad, zapatos de seguridad: reemplazo de PA o PPO reforzados con fibra corta. Hoja de datos de referencia Sobre nosotros Xiamen LFT Composite Plastics Co., Ltd. es un proveedor líder de termoplásticos reforzados con fibra de vidrio larga (LGF) y fibra de carbono larga (LCF). Nuestros materiales LFT son compatibles con moldeo por inyección y extrusión, y están disponibles en longitudes de fibra de 5 a 25 mm, adaptadas a las necesidades del cliente. Con certificación ISO9001 e IATF16949, nuestros productos están patentados y se utilizan ampliamente en aplicaciones de automoción, electrónica, industria y defensa. Lo que ofrecemos Datos técnicos y orientación para materiales LFT y LFRT. Recomendaciones de diseño de moldes para una producción optimizada. Soporte de moldeo por inyección y extrusión para una calidad constante del producto.

- Relleno de polipropileno lgf GFRP 30

- Polímero termoplástico de grado virgen

- Piezas de automóvil LFT-G, piezas de electrodomésticos

- Resina PP GF fabricada en China, plástico modificado

- Compuestos de fibra larga pp en lugar de metal y acero

- Compuesto de PP moldeado por inyección

Etiquetas :

correo electrónico

correo electrónico español

español English

English français

français Deutsch

Deutsch русский

русский italiano

italiano português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文