nuevo blog

â ¿Qué es el compuesto reforzado con fibras largas (LFT-G)?

La longitud incluida de Fibra reforzada es equivalente a la longitud de partículas de plástico termoplástico de más de 6 mm.

â ¿Cuáles son los beneficios de usar LFT-G?

Beneficios para propietarios de empresas y fábricas:

a. Plástico en lugar de acero: El antiguo material metálico con alta resistencia, resistencia al calor y otras características, es el material preferido para muchos productos industriales, y la desventaja es que no es adecuado para formar formas complejas. El material reforzado con fibra de vidrio larga (L.F.R.T) es el más similar a las propiedades del metal y parece ser la mejor opción para reemplazar el metal.

b. Ligero: como el peso de las piezas metálicas en general es relativamente pesado, con la tendencia de protección ambiental y ahorro de energía en los países avanzados de todo el mundo, la industria ha iniciado la tendencia de "aligerar".

do. Propiedades mecánicas de alta resistencia: para las piezas hechas de LFRT, las fibras largas forman una estructura de red 3D tridimensional en el interior y atraviesan la resina de matriz como un esqueleto reforzado, de modo que las piezas puedan soportar mayores tensiones y cargas, y absorber eficazmente el exterior. energía de impacto, de modo que los productos terminados tengan una excelente resistencia específica, rigidez, resistencia al impacto y estabilidad dimensional. Y resistencia a la temperatura, baja deformación, resistencia a la fluencia, bajo coeficiente de expansión térmica y otras ventajas.

â El uso de LFT-G para contribuir a la protección del medio ambiente

A diferencia de los materiales termoendurecibles generales, LFT-G es un material termoplástico y sus residuos se pueden reciclar y triturar, y reutilizar o mezclar nuevamente, el rendimiento no se reducirá significativamente y puede reducir el costo de eliminación de residuos en la última sección.

â ¿Cuáles son los beneficios de usar LFT-G? ¿Cuáles son los beneficios para los empleados?

En comparación con el procesamiento de materiales metálicos/termoestables, LFT-G es un material con bajo contenido de VOC y no libera ninguna sustancia tóxica.

â ¿Cuáles son las ventajas de LFT-G en comparación con los productos de otras empresas?

a. Unidad de proceso original Eurostandard computarizada/automatizada, calidad estable, excelente recubrimiento entre resina y fibra.

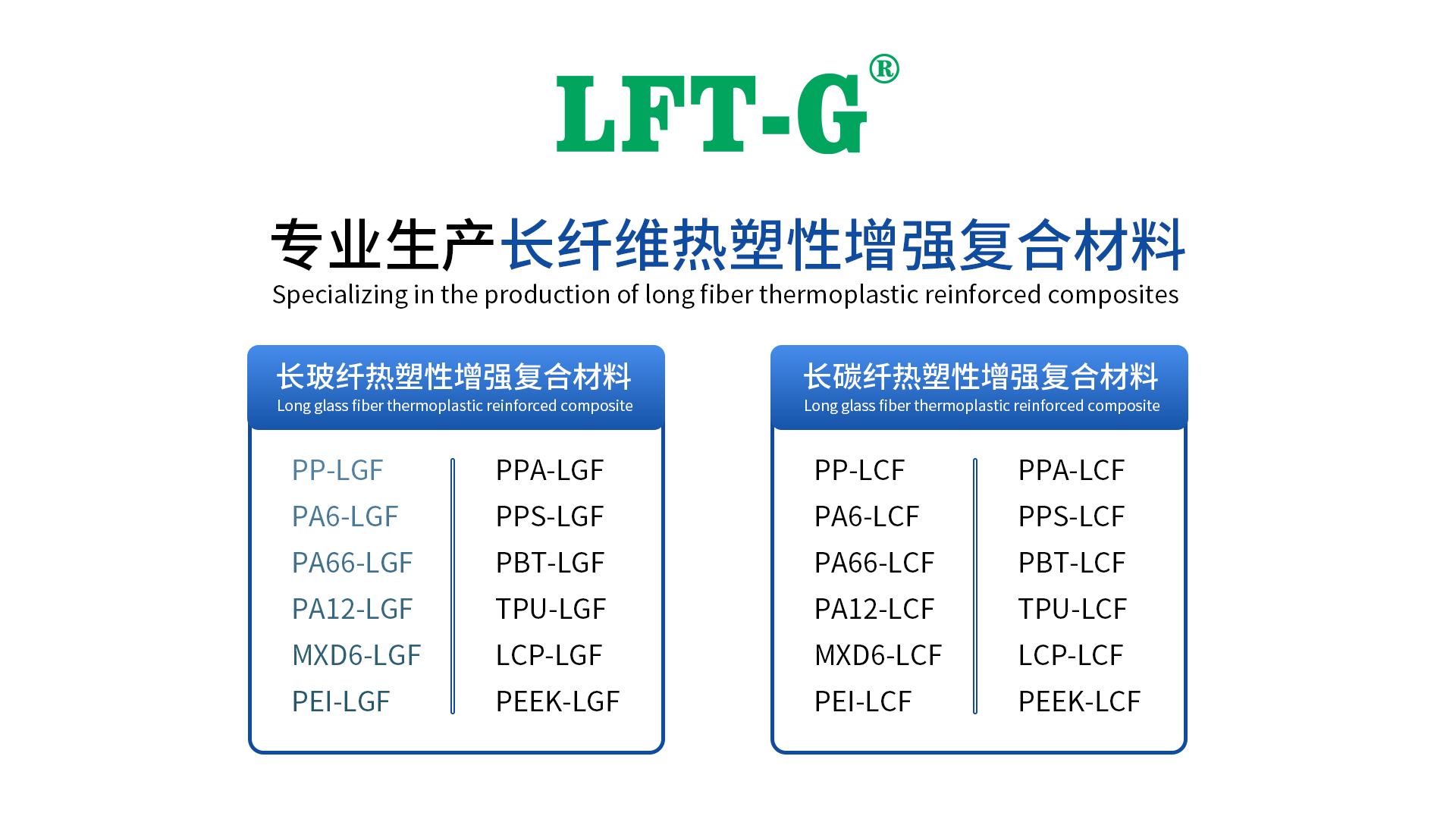

B. la variedad de productos, incluidos PP, PA6, PA66, TPU, PA12, PPS, PPA y otros materiales.

c. El equipo de servicio técnico de Dadong ayudará a los clientes a abordar cuestiones relevantes durante todo el proceso, como sugerencias de especificaciones, parámetros de procesamiento, moldes, aplicación del producto, etc., para garantizar que el rendimiento de los materiales pueda cumplir con los requisitos del cliente.

â ¿En qué industrias se puede utilizar LFT-G?

Es adecuado para piezas de automóviles, herramientas manuales, equipos deportivos (bicicletas/esquí/aparejos de pesca), piezas de calzado, ventiladores industriales y otras industrias.

â ¿Costará más usar LFT-G?

a. El precio unitario de los materiales es ligeramente más alto que el de la aleación de aluminio, pero puede ahorrar el costo/tiempo del procesamiento secundario del metal, lo cual es relativamente favorable en general.

b. El precio unitario de los materiales es ligeramente más alto que el de los compuestos reforzados con fibras discontinuas homogéneas, pero LFT-G tiene una alta estabilidad dimensional y no es fácil de deformar. Se puede ensamblar después del desmolde, lo que puede ahorrar el tiempo de enfriamiento/mantenimiento de presión del conformado y el costo/tiempo de fijar herramientas personalizadas.

â ¿Usa la apariencia de moldura LFT-G para que la fibra flote?

La selección de sustrato de resina de Datong es resina de alta movilidad, la apariencia del producto terminado es buena, si la temperatura del molde, el rendimiento es mejor.

â ¿Utilizar LFT-G desgastará más tornillo de máquina de inyección?

El tornillo de desgaste es principalmente la sección transversal afilada en ambos extremos de la fibra. Las fibras largas y las fibras cortas son estructuras de dos puntos y de una línea, pero en la misma proporción, el área de la sección transversal afilada de la fibra corta es mayor que la de la fibra larga, por lo que el desgaste de las dos en el tornillo es similar.

A través de las preguntas y respuestas anteriores, ¿sabe más sobre LFT-G material compuesto reforzado con fibra larga? Si desea saber más, no dude en contactarnos.