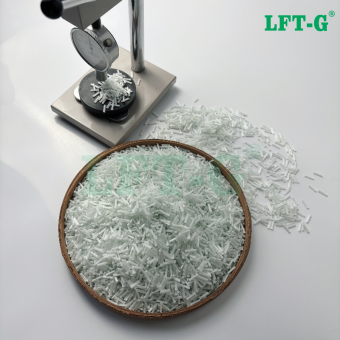

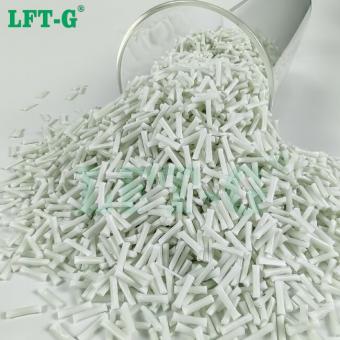

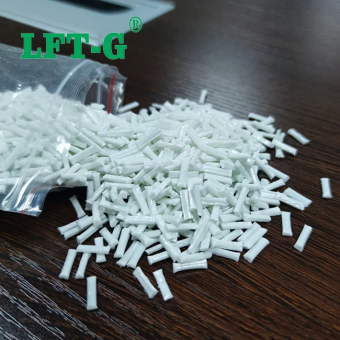

En estos días, el mundo de los secadores de cabello apareció inesperadamente. Antes de la ruta de gama alta de Dyson, después de la ruta civil de mijo. En todos los mercados pacíficos, todo tipo de marcas de secadores de cabello domésticos saltaron repentinamente para apoderarse del mercado de Dyson y suprimir el precio de Xiaomi. En un instante, todo tipo de secadores de pelo a la vista del público. Según las estadísticas, en la primera mitad de 2021, las ventas minoristas de secadores de cabello en China fueron de 2760 millones de yuanes, un 41,3 % más que el año anterior, y las ventas minoristas fueron de 13,81 millones de unidades, un 40,9 % más que el año anterior. Con el desarrollo de 5G, el secador de cabello chino ha ingresado a la próxima generación, y la demanda de la gente por un secador de cabello personalizado también está aumentando. At the same time, glass fiber reinforced nylon has quietly become the star material of hair dryer shell, and become the landmark material of the next generation of high-end hair dryer. Glass fiber reinforced PA66 is commonly used in the mouthpiece of high-quality hair dryers to increase strength and heat capacity. However, as the function of the hair dryer becomes more and more demanding, ABS as the main material of the shell is gradually replaced by glass fiber reinforced PA66. At present, the main factors affecting the preparation of high performance glass fiber reinforced PA66 composites include the length of glass fiber, the surface treatment of glass fiber and its retention length in the matrix. So let's take a look at the influencing factors of glass fiber reinforced PA66 production 1. The length of glass fiber The length of fiber is one of the main factors to determine the fiber reinforced composite. In ordinary short fiber reinforced thermoplastics, the fiber length is only (0.2~0.6) mm, so that when the material is damaged by force, because of the short length of the fiber, so that its strength is basically not used, and the purpose of using fiber reinforced nylon is to use the high rigidity and high strength of the fiber to improve the mechanical properties of nylon, So fiber length plays an important role in mechanical properties of products. Compared with short glass fiber reinforced nylon, the modulus, strength, creep resistance, fatigue resistance, impact resistance, heat resistance and wear resistance of long glass fiber reinforced nylon have been improved, and its application in automobile, electrical appliances, machinery and military industry has been expanded. 2. Surface treatment of glass fiber The binding force between glass fiber and matrix is another important factor affecting the mechanical properties of composite materials. Glass fiber reinforced polymers have good properties only when effective interfacial bonding is formed. For glass fiber reinforced thermosetting resin or polar thermoplastic resin composites, the surface of glass fiber can be treated with coupling agent to fo...

ver más

correo electrónico

correo electrónico español

español English

English français

français Deutsch

Deutsch русский

русский italiano

italiano português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文