fondo material

Nylon 6(PA6), also known as polyamide 6, its mechanical strength and crystallization is good, and has the characteristics of corrosion resistance, wear resistance, etc., in the automobile industry, rail transit, film packaging, electronic appliances and textile and other major fields to achieve a wide range of applications. Although its comprehensive performance is excellent, it also has a series of shortcomings, such as PA6 does not have strong acid and alkali resistance, low impact strength at low temperature and dry state, and its hydrophilic base will cause a high water absorption rate, and the elastic modulus, creep resistance, impact strength and so on will be greatly reduced after water absorption, thus affecting the dimensional stability of products and the electrical properties of products. Therefore, it is necessary to study the modification of PA6.

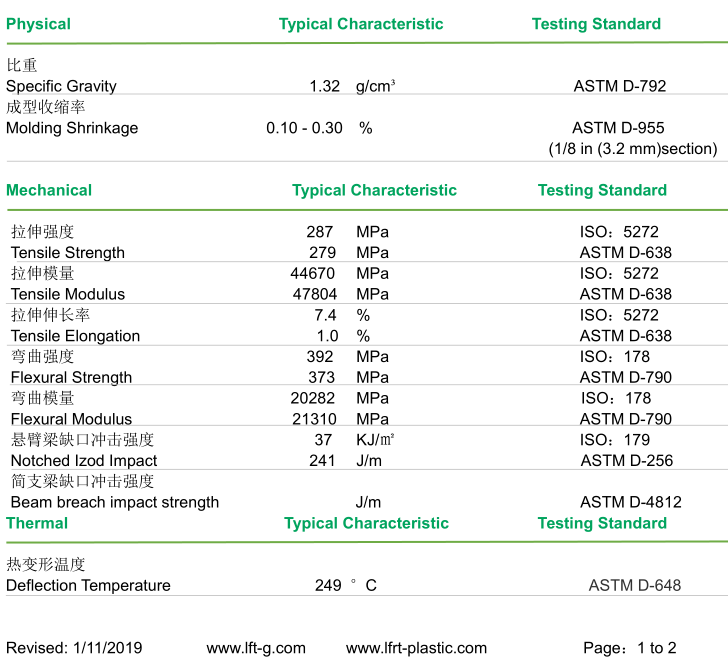

PA-LGF has excellent performance and has great application potential in automotive, machinery, electrical appliances, military and other fields. With the continuous progress of science and technology, the requirements for PA6 materials in various application fields are getting higher and higher. Therefore, further study on LGF filling modification of PA6 to make it have more excellent mechanical properties has become a focus of extensive attention of researchers in recent years.

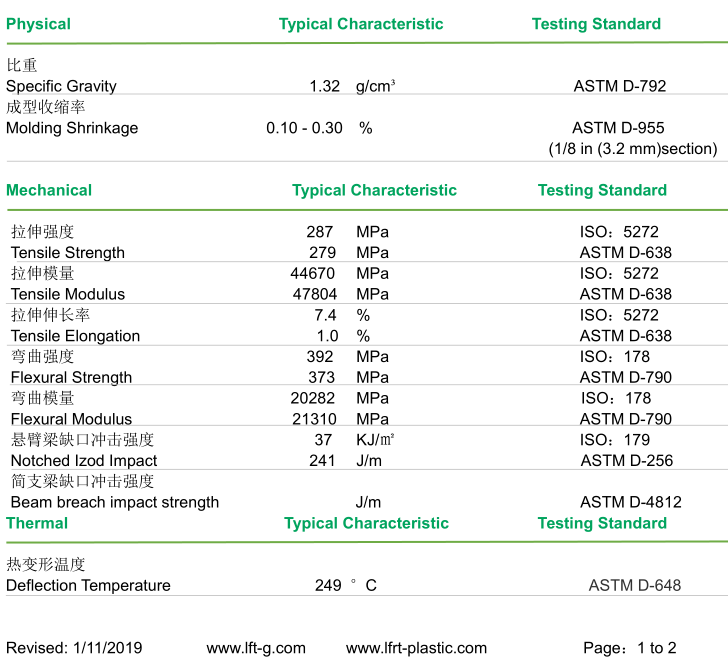

Material feature

The raw material of PA has a broad source, which is the basis of its large-scale industrial production. Due to the regular arrangement of molecular structure, many hydrogen bonds can be formed between macromolecules of PA, so it has high crystallinity and outstanding characteristics in mechanical, chemical and thermal properties, including:

(1) high tensile strength and bending strength;

(2) good impact resistance;

(3) with high heat resistance;

(4) It has the characteristics of wear-resisting and self-lubrication, which is incomparable to metal materials;

(5) Good swelling resistance and corrosion resistance to chemical solvents and drugs;

(6) Good flow processing, can be used for injection molding, extrusion, blow molding and other methods of product processing;

(7) Excellent barrier performance;

(8) has a very high chemical activity, which the polar groups can react with the monomer and polymer containing polar groups, the formation of new polymer compounds.

Material image

Company introduction

Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplstic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length.

Los termoplásticos reforzados con infiltración continua de fibra larga de la compañía han pasado la certificación del sistema ISO9001 y 16949. y los productos han obtenido lotes de marcas registradas y patentes nacionales. En particular, la serie LFT de fibra de carbono producida por nuestra empresa ha roto el bloqueo técnico. Para uso doméstico: automoción, piezas militares, armas de fuego, aeroespacial, nuevas energías, equipos médicos, energía eólica eléctrica, equipos deportivos y otros campos requieren plásticos de ingeniería especiales termoplásticos de alto rendimiento. Y otras industrias de innovación de nuevas tecnologías brindan soporte técnico y de productos.

Conseguirás:

1. Parámetros técnicos del material LFT y LFRT y diseño de vanguardia;

2. Diseño y recomendaciones del frente del molde;

3. Brindar soporte técnico como moldeo por inyección y moldeo por extrusión.

correo electrónico

correo electrónico español

español English

English français

français Deutsch

Deutsch русский

русский italiano

italiano português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文