Artículo No.:

PA6-NA-LGF50Pago:

T/T or L/C (other payment ways also can be diorigen del producto:

Xiamen, ChinaColor:

Original color (also can be customized)Puerto de embarque:

Xiamen, China¿Qué es el plástico PA6?

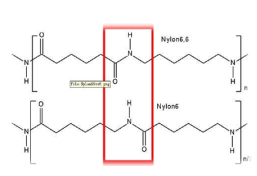

La poliamida (PA), generalmente llamada nailon, es un polímero de heterocadena que contiene un grupo amida (-NHCo -) en la cadena principal. Se puede dividir en grupo alifático y grupo aromático. Es el material de ingeniería termoplástico desarrollado más temprano y más utilizado.

La cadena principal de poliamida contiene muchos grupos amida repetidos, se usa como un plástico llamado nailon, se usa como una fibra sintética llamada nailon. Se puede preparar una variedad de poliamidas diferentes según el número de átomos de carbono contenidos en aminas binarias y ácidos dibásicos o aminoácidos. En la actualidad existen decenas de poliamidas, entre las cuales la poliamida-6, la poliamida-66 y la poliamida-610 son las más utilizadas.

La poliamida-6 es una poliamida alifática, con peso ligero, fuerte resistencia, resistencia al desgaste, resistencia débil a ácidos y álcalis y algunos solventes orgánicos, fácil moldeo y procesamiento y otras propiedades excelentes, ampliamente utilizada en fibra, plásticos de ingeniería y películas delgadas y otros campos. , pero el segmento de la cadena molecular PA6 contiene grupos amida de polaridad fuerte, enlaces de hidrógeno fáciles de formar con moléculas de agua, el producto tiene las desventajas de una gran absorción de agua, poca estabilidad dimensional, baja resistencia al impacto en estado seco y baja temperatura, fuerte resistencia a ácidos y álcalis .

Advantages of nylon 6:

High mechanical strength, good toughness, high tensile and compressive strength.

Outstanding fatigue resistance, the parts after repeated bending can still maintain the original mechanical strength.

High softening point, heat resistant.

Smooth surface, small friction coefficient, wear-resistant.

Corrosion resistance, very resistant to alkali and most salts, also resistant to weak acids, oil, gasoline, aromatic compounds and general solvents, aromatic compounds are inert, but not resistant to strong acids and oxidants. It can resist the corrosion of gasoline, oil, fat, alcohol, alkaline and so on, and has good anti-aging ability.

It is self-extinguishing, non-toxic, odorless, good weather resistance, inert to biological erosion, and has good antibacterial and mildew resistance.

Has excellent electrical performance, good electrical insulation, nylon volume resistance is high, high breakdown voltage resistance, in dry environment, can work frequency insulation material, even in high humidity environment still has good electrical insulation.

Light weight, easy dyeing, easy forming, because of low melting viscosity, can flow quickly.

Disadvantages of Nylon 6:

Easy to absorb water, water absorption, saturated water can reach more than 3%.

Poor light resistance, in the long-term high temperature environment will oxidize with oxygen in the air, the color turns brown at the beginning, and the subsequent surface is broken and cracked.

Injection molding technology requirements more strict, the existence of trace moisture will cause great damage to the quality of molding; The dimensional stability of the product is difficult to control because of thermal expansion. The existence of sharp Angle in the product will lead to stress concentration and reduce the mechanical strength; If the wall thickness is not uniform, it will lead to the distortion and deformation of the parts. High precision of equipment is required in post-processing.

Will absorb water, alcohol and swelling, not resistant to strong acid and oxidant, can not be used as acid-resistant materials.

Why filling Long Glass Fiber?

PA6 has excellent properties such as light weight, strong strength, abrasion resistance, weak acid and alkali resistance and some organic solvents, and easy molding and processing. It is widely used in the fields of fibers, engineering plastics and films. However, the molecular chain segment of PA6 contains highly polar amide groups, which are easy to form hydrogen bonds with water molecules. The product has the disadvantages of large water absorption, poor dimensional stability, low impact strength in dry state and low temperature, strong acid and alkali resistance. With the development of science and technology and the improvement of life quality, the defects in some properties of traditional PA6 materials have limited its development in some fields. In order to improve the performance of PA6 and expand its application field, PA6 should be modified.

Filling enhancement modification is a common method for physical modification of PA6. It refers to the modification of PA6 by adding fillers such as glass fiber and carbon fiber into the matrix to significantly improve the mechanical properties, flame retardant properties, thermal conductivity and dimensional stability of the material.

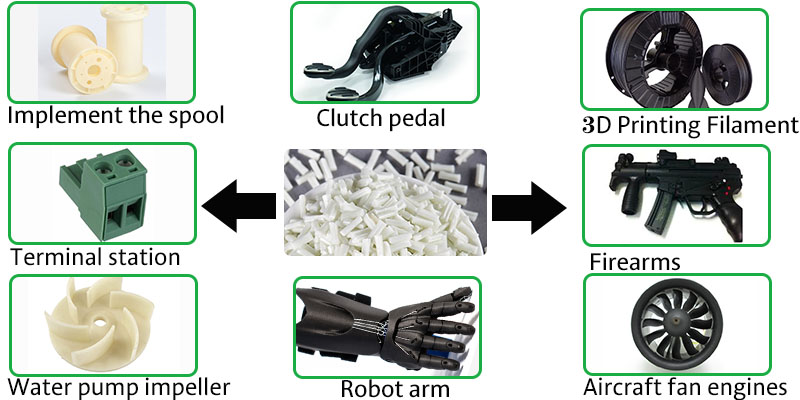

What is application of PA6-LGF?

Modified section of 30% long glass fiber reinforced PA6 is the ideal material for processing power tool shell, power tool parts, engineering machinery parts and automobile parts. Its mechanical properties, dimensional stability, heat resistance and aging resistance have been significantly improved. The fatigue resistance strength is 2.5 times that of unenhanced, and the modification effect is the most obvious

Processing and forming points of modified PA6 filling 30% LGF

30% glass fiber reinforced PA6 product shrinkage can be reduced to 0.3%. The shrinkage rate of pure PA6 is between 1% and 1.5%, which can be reduced to about 0.3% after adding 30% glass fiber reinforcement. The practical experience shows that the more glass fiber added, the smaller the shrinkage of PA6 resin. But with the increase of the amount of fiber added, it will also cause the surface floating fiber, poor compatibility and other consequences, 30% glass fiber reinforcement effect is relatively good.

30% glass fiber reinforced PA6 recycled material should not be used more than 3 times. 30% glass fiber reinforced PA6 does not contain any recycled material, but if customers use too much recycled material, easy to cause product discoloration or mechanical and physical properties of the sharp decline, the dosage should be controlled below 25%, otherwise it will cause the fluctuation of process conditions, recycled material and new material must be dried before mixed use.

Put the product into hot water and cool it slowly. Because the glass fiber will be oriented along the direction of flow in the injection molding process, resulting in the enhancement of mechanical properties and shrinkage in the direction of orientation, resulting in product deformation and warping, therefore, in the mold design, the position and shape of the gate should be reasonable, the process can improve the temperature of the mold, the product should be put into hot water to cool slowly.

Customers&Stuffs

Certificates