poliamida reforzada con fibra de carbono larga nylon pa66 Reparado por el proceso de impregnación de la solución. fibra de carbono larga reforzada pa66 Gama de aplicaciones típicas de piezas de automóviles, piezas mecánicas, productos eléctricos y electrónicos, accesorios de ingeniería y otros productos.

-

Resistencia al desgaste con relleno de fibra de carbono larga de poliamida 66 Xiamen LFT-G para autopartesPropiedades físicas de los materiales de nailon. Excelentes propiedades mecánicas: alta resistencia mecánica, buena tenacidad. Excelente autohumectación, resistencia al desgaste: pequeño coeficiente de fricción, larga vida útil como componente de transmisión. Excelente resistencia al calor: la temperatura de distorsión del calor PA66 es muy alta, se puede utilizar durante mucho tiempo a 150 grados Celsius, PA66 después del refuerzo con fibra de vidrio, la temperatura de distorsión del calor es de 252 grados Celsius o más. Excelentes propiedades de aislamiento eléctrico: su resistencia al volumen es muy alta, alta resistencia al voltaje de ruptura, es un excelente material de aislamiento eléctrico/electrónico. Introducción de pellets LCF rellenos de Nylon66 PA66 es un plástico de ingeniería de alto rendimiento, absorción de humedad, mala estabilidad dimensional de los productos, resistencia y dureza del metal. Para superar estas deficiencias, ya en la década de 1970, la gente usaba fibra de carbono y fibra de vidrio para mejorar su rendimiento. PA66 reforzado con materiales de fibra de carbono en los últimos años el desarrollo es más rápido, porque PA66 y la fibra de carbono tienen un excelente rendimiento en el campo de los materiales plásticos de ingeniería, el material compuesto encarna de forma integral la superioridad de los dos, como la resistencia y la rigidez que el PA66 no mejorado es mucho mayor que el de la fluencia a alta temperatura es pequeño, la estabilidad térmica de una mejora significativa en la precisión dimensional de la buena, resistente al desgaste. En la actualidad, los materiales compuestos de fibra de carbono PA66 son principalmente partículas reforzadas con fibra de carbono cortas o largas y se han utilizado ampliamente en la industria automotriz, artículos deportivos, maquinaria textil, materiales aeroespaciales y otros campos. La fibra de carbono es liviana, tiene alta resistencia a la tracción, resistencia a la abrasión, resistencia a la corrosión, resistencia a la fluencia, conductividad eléctrica, transferencia de calor, etc. Es muy similar a la fibra de vidrio, pero superior a la fibra de vidrio. En comparación con la fibra de vidrio, el módulo es 3 veces mayor, que es un material con alta rigidez y alta resistencia. Hoja de datos de PA6-LCF como referencia A partir de los experimentos del departamento técnico, sabemos que la resistencia a la flexión, el módulo de elasticidad de flexión, la resistencia al impacto y la resistencia al corte plano del material de fibra de carbono PA66 con fibra añadida aumentan con el aumento del contenido de fibra de carbono, la resistencia al corte transversal disminuyó ligeramente. En general, la resistencia del material ha aumentado drásticamente. Aplicación de PA66-LCF Certificado Certificación del Sistema de Gestión de Calidad ISO9001/16949 Certificado de Acreditación de Laboratorio Nacional Empresa de innovación en plásticos modificados Certificado honorario Pruebas REACH y ROHS de metales pesados Fábrica y laboratorio Preguntas y respuestas 1. Is there a unified reference data for carbon fiber product performance?The performance of specific carbon fiber filaments is fixed, such as Toray's carbon fiber filaments, T300, T300J, T400, T700 and so on, there are a series of parameters can be traced. However, there is no uniform standard to measure the carbon fiber composite products. Firstly, the different types of raw materials selected will lead to different performance of the products, and then due to the choice of matrix and the different design of the products, it will lead to different performance of the products. In addition to some common carbon fiber tubes, carbon fiber boards and other conventional parts, most of the carbon fiber products in the production of the sample before the test to determine whether the performance of the product is in line with the use of the expected standard, and as a base point, so as to carry out the production and use of large quantities.2. Are carbon fiber composite products expensive?The price of carbon fiber composite products is closely related to the price of raw materials, the level of technology and the quantity of products. Some products of the industrial environment requirements are high, the performance of carbon fiber products and materials have special requirements, which requires the selection of specific raw materials, raw materials, the higher the performance of the natural price of the more expensive, such as the application of orthopedic carbon fiber PEEK thermoplastic materials. Of course, the more complex the production process, the greater the working time and workload, and the production cost increases. However, the larger the order quantity, the lower the cost per piece, once the mass production of a particular carbon fiber product has been established. In the long run, the superior performance of carbon fiber will prolong the service life of the product, reduce the number of mainten...

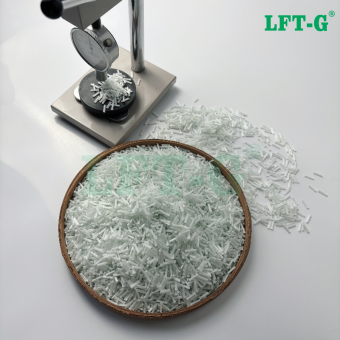

- Materias primas plásticas PA66 moldeadas por inyección.

- PA66 pellets puros reciclados de peso ligero

- fibra de carbono larga pa66 color negro natural

- gránulos pa66 lcf en lugar de polímeros metálicos

- Aparato electrónico de baja deformación

- autopartes y piezas aeroespaciales

Etiquetas :

-

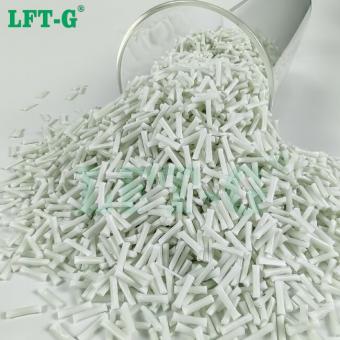

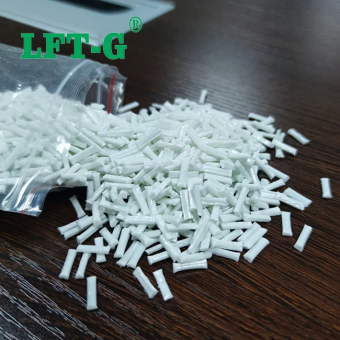

Gránulos de moldeo por inyección de compuestos rellenos de fibra de carbono larga de poliamida 66 LFT-G®¿Qué son los materiales LFT? Materiales de ingeniería termoplásticos reforzados con fibra larga LFT, en comparación con los materiales termoplásticos reforzados con fibra corta ordinarios (la longitud de la fibra es inferior a 1-2 mm), el proceso LFT produce fibras de material de ingeniería termoplástico en longitudes de 5-25 mm. Las fibras largas se impregnan con la resina a través de un sistema de molde especial para obtener tiras largas que quedan completamente impregnadas con la resina y luego se cortan a la longitud necesaria. La resina base más utilizada es el PP, seguida de PA6, PA66, PPA,PA12,MXD6,PBT, PET,TPU,PPS, LCP,PEEK, etc. Las fibras convencionales incluyen fibra de vidrio, fibra de carbono, las fibras especiales incluyen fibra de basalto y cuarzo. fibra, etc. Dependiendo del uso final, los productos terminados pueden usarse para moldeo por inyección, extrusión, moldeo, etc., o usarse directamente para plástico en lugar de acero y productos termoestables. Los compuestos largos reforzados con fibra de carbono pueden resolver sus problemas cuando otros métodos de plásticos reforzados no brindan el rendimiento que necesita o si desea reemplazar el metal con plástico. Los compuestos largos reforzados con fibra de carbono pueden reducir de manera rentable el costo de los bienes y mejorar efectivamente las propiedades mecánicas del polímero de ingeniería. Las fibras largas se pueden distribuir uniformemente dentro del producto para formar un esqueleto de red, mejorando así las propiedades mecánicas del producto material. ¿Qué es el refuerzo de fibra de carbono larga de poliamida 66? El nailon 6,6, también escrito como nailon 6-6, nailon 66 o nailon 6/6, es una versión más cristalina del nailon 6. También se lo conoce como poliamida 66 o PA 66. Tiene propiedades mecánicas mejoradas debido a su estructura molecular más ordenada. El nailon 66 para mecanizado tiene una resistencia mejorada a la temperatura y tasas más bajas de absorción de agua en comparación con el nailon 6 estándar. Las ventajas del nailon 6,6 son que el límite elástico es mayor que el del nailon 6 y el nailon 610. Tiene alta resistencia, tenacidad y rigidez. y bajo coeficiente de fricción en un amplio rango de temperaturas. Además, es resistente al aceite y a reactivos químicos y disolventes. Sin embargo, PA66 tiene una fuerte higroscopicidad y una mala estabilidad dimensional, lo que limita su aplicación. Para obtener un material de ingeniería de nailon 66 con mayor resistencia, se debe modificar con refuerzo de fibra de carbono. Las propiedades mecánicas del nailon 66 reforzado con fibra de carbono larga (LCFR-PA66) son obviamente mejores que las del nailon 66 reforzado con fibra de carbono corta (SCFR-PA66), y el rendimiento del procesamiento de moldeo también es mejor. Puede moldearse mediante diversos métodos de moldeo, como moldeo por inyección y moldeo por compresión, y también se pueden formar componentes complejos. Por lo tanto, el nailon 66 reforzado con fibra de carbono larga puede usarse ampliamente en materiales de construcción, aeroespacial, dispositivos electrónicos, muebles y otros campos, especialmente en el mercado de aplicaciones de la industria automotriz. El proceso de producción del nailon 66 reforzado con fibra de carbono larga es diferente del del nailon 66 reforzado con fibra de carbono corta. La partícula de nailon 66 reforzado con fibra de carbono corta se corta bajo la fricción y el corte del tornillo y el cilindro, y la partícula de nailon 66 reforzada con fibra de carbono corta se corta bajo la fricción y el corte del tornillo y el cilindro. La partícula se obtiene con una longitud de monofilamento de fibra de carbono de aproximadamente 0,5 mm. La longitud de algunos monofilamentos de fibra de carbono en el producto final es menor que la longitud crítica del refuerzo, y la fibra de carbono es fácil de extraer de la matriz de nailon 66 cuando el producto está sometido a tensión. La resistencia de la fibra de carbono no se aprovecha al máximo y las propiedades mecánicas del producto no son altas. El nailon 66 reforzado con fibra de carbono larga tiene un mejor efecto de refuerzo y estabilidad dimensional, y la rigidez, tracción, flexión, resistencia al impacto y resistencia a la fatiga de los productos fabricados son mejores y la vida útil es más larga. Preguntas y respuestas P: ¿La inyección de fibra de vidrio larga y fibra de carbono larga tiene requisitos especiales para las máquinas y moldes de moldeo por inyección? R: Ciertamente existen requisitos. especialmente desde la estructura de diseño del producto, así como la boquilla de tornillo de la máquina de moldeo por inyección y el proceso de moldeo por inyección de la estructura del molde, se deben considerar los requisitos de la fibra larga. P. El producto es fácil de quebradizo, por lo que cambiar al uso de materiales termoplásticos reforzados con fibra larga puede resolver este problema. R: Es necesario mejorar las propiedades mecánicas genera...

- Compuestos de resina termoplástica reforzada

- Nylon PA 6.6 plástico de alta resistencia

- Fabricante chino de plástico de ingeniería.

- Materiales mejorados con filamento CF

- fibra de corte largo en lugar de metal y acero

- altas propiedades mecánicas

Etiquetas :

-

Resistencia al desgaste con relleno de fibra de carbono larga de poliamida 66 Xiamen LFT-G para autopartesPropiedades físicas de los materiales de nailon. Excelentes propiedades mecánicas: alta resistencia mecánica, buena tenacidad. Excelente autohumectación, resistencia al desgaste: pequeño coeficiente de fricción, larga vida útil como componente de transmisión. Excelente resistencia al calor: la temperatura de distorsión del calor PA66 es muy alta, se puede utilizar durante mucho tiempo a 150 grados Celsius, PA66 después del refuerzo con fibra de vidrio, la temperatura de distorsión del calor es de 252 grados Celsius o más. Excelentes propiedades de aislamiento eléctrico: su resistencia al volumen es muy alta, alta resistencia al voltaje de ruptura, es un excelente material de aislamiento eléctrico/electrónico. Introducción de pellets LCF rellenos de Nylon66 PA66 es un plástico de ingeniería de alto rendimiento, absorción de humedad, mala estabilidad dimensional de los productos, resistencia y dureza del metal. Para superar estas deficiencias, ya en la década de 1970, la gente usaba fibra de carbono y fibra de vidrio para mejorar su rendimiento. PA66 reforzado con materiales de fibra de carbono en los últimos años el desarrollo es más rápido, porque PA66 y la fibra de carbono tienen un excelente rendimiento en el campo de los materiales plásticos de ingeniería, el material compuesto encarna de forma integral la superioridad de los dos, como la resistencia y la rigidez que el PA66 no mejorado es mucho mayor que el de la fluencia a alta temperatura es pequeño, la estabilidad térmica de una mejora significativa en la precisión dimensional de la buena, resistente al desgaste. En la actualidad, los materiales compuestos de fibra de carbono PA66 son principalmente partículas reforzadas con fibra de carbono cortas o largas y se han utilizado ampliamente en la industria automotriz, artículos deportivos, maquinaria textil, materiales aeroespaciales y otros campos. La fibra de carbono es liviana, tiene alta resistencia a la tracción, resistencia a la abrasión, resistencia a la corrosión, resistencia a la fluencia, conductividad eléctrica, transferencia de calor, etc. Es muy similar a la fibra de vidrio, pero superior a la fibra de vidrio. En comparación con la fibra de vidrio, el módulo es 3 veces mayor, que es un material con alta rigidez y alta resistencia. Hoja de datos de PA6-LCF como referencia A partir de los experimentos del departamento técnico, sabemos que la resistencia a la flexión, el módulo de elasticidad de flexión, la resistencia al impacto y la resistencia al corte plano del material de fibra de carbono PA66 con fibra añadida aumentan con el aumento del contenido de fibra de carbono, la resistencia al corte transversal disminuyó ligeramente. En general, la resistencia del material ha aumentado dramáticamente. Aplicación de PA66-LCF Certificado Certificación del Sistema de Gestión de Calidad ISO9001/16949 Certificado de Acreditación de Laboratorio Nacional Empresa de innovación en plásticos modificados Certificado honorario Pruebas REACH y ROHS de metales pesados Fábrica y laboratorio Preguntas y respuestas 1. ¿Existen datos de referencia unificados para el rendimiento de los productos de fibra de carbono? El rendimiento de filamentos de fibra de carbono específicos es fijo, como los filamentos de fibra de carbono de Toray, T300, T300J, T400, T700, etc., se pueden rastrear una serie de parámetros. Sin embargo, no existe un estándar uniforme para medir los productos compuestos de fibra de carbono. En primer lugar, los diferentes tipos de materias primas seleccionadas conducirán a un rendimiento diferente de los productos y luego, debido a la elección de la matriz y al diseño diferente de los productos, conducirán a un rendimiento diferente de los productos. Además de algunos tubos de fibra de carbono comunes, tableros de fibra de carbono y otras piezas convencionales, la mayoría de los productos de fibra de carbono en la producción de la muestra antes de la prueba para determinar si el rendimiento del producto está en línea con el uso del estándar esperado. , y como punto base, para realizar la producción y utilización en grandes cantidades. 2. ¿Son caros los productos compuestos de fibra de carbono? El precio de los productos compuestos de fibra de carbono está estrechamente relacionado con el precio de las materias primas, el nivel de tecnología y la cantidad de productos. Algunos productos de los requisitos del entorno industrial son altos, el rendimiento de los productos y materiales de fibra de carbono tiene requisitos especiales, lo que requiere la selección de materias primas específicas, materias primas, cuanto mayor sea el rendimiento del precio natural, más caro, como el Aplicación de materiales termoplásticos ortopédicos PEEK de fibra de carbono. Por supuesto, cuanto más complejo es el proceso de producción, mayor es el tiempo y la carga de trabajo, y aumenta el coste de producción. Sin embargo, cuanto mayor sea la cantidad del pedido, menor será el costo por pieza, una vez que se haya establec...ver más

-

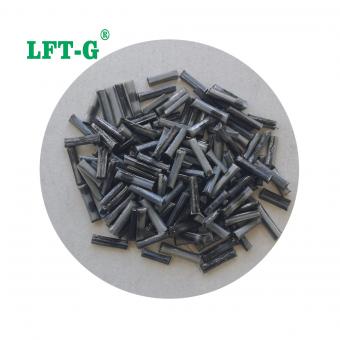

Refuerzo largo de fibra de carbono LFT Poliamida 66 de alto rendimientoPoliamida 66 fibra de carbono itinerante Nylon color negro con resistencia al calor

- La fibra de carbono larga mejora los pellets.

- Fibra de carbono itinerante PA66 en lugar de metal y acero

- Gránulos compuestos de Nylon66 para inyección.

- Compuesto de fibra larga PA66 de alta calidad.

- Compuesto de fibra larga de poliamida

- Plástico virgen PA6 LCF40 para repuestos de automóviles

Etiquetas :

-

Refuerzo largo de fibra de carbono LFT Poliamida 66 de alto rendimientoPoliamida 66 fibra de carbono itinerante Nylon color negro con resistencia al calorver más

-

LFT Poliamida 66 nailon largo de fibra de carbono de alto rendimientoPoliamida 66 fibra de carbono itinerante Nylon color negro con resistencia al calorver más

-

Pellets largos reforzados con fibra de carbono de material compuesto de poliamida 66 de Xiamen LFTNúmero de producto: PA66-NA-LCF50 Especificación de fibra: 20%-60% Característica del producto: Alta tenacidad, Peso ligero, Alta resistencia, Resistencia al desgaste, Resistencia a la corrosión, Resistencia a la fluencia, Conducción, Transferencia de calor Aplicación del producto: ala de avión, ala de pato, ala estable, góndola y otros campos aeroespaciales.

- Compuestos ligeros de pa66 en lugar de metal.

- Campos aeroespaciales materiales de alta tecnología.

- conducción nylon 6.6 fibra de carbono

- La muestra disponible se puede personalizar pa66 lft

- Pa66 modificado compuesto de color negro para piezas de automóviles

- Material termoplástico LFT-G moldeo por inyección pa6/6

Etiquetas :

-

LFT Poliamida 66 largo de alto rendimiento reforzado con fibra de carbonoPoliamida 66 fibra de carbono itinerante Nylon color negro con resistencia al calorver más

-

LFT Poliamida 66 nailon largo de fibra de carbono de alto rendimientoPoliamida 66 fibra de carbono itinerante Nylon color negro con resistencia al calorver más

-

Resistencia al desgaste con relleno de fibra de carbono larga de poliamida 66 Xiamen LFT-G para autopartesPropiedades físicas de los materiales de nailon. Excelentes propiedades mecánicas: alta resistencia mecánica, buena tenacidad. Excelente autohumectación, resistencia al desgaste: pequeño coeficiente de fricción, larga vida útil como componente de transmisión. Excelente resistencia al calor: la temperatura de distorsión del calor PA66 es muy alta, se puede utilizar durante mucho tiempo a 150 grados Celsius, PA66 después del refuerzo con fibra de vidrio, la temperatura de distorsión del calor es de 252 grados Celsius o más. Excelentes propiedades de aislamiento eléctrico: su resistencia al volumen es muy alta, alta resistencia al voltaje de ruptura, es un excelente material de aislamiento eléctrico/electrónico. Introducción de pellets LCF rellenos de Nylon66 PA66 es un plástico de ingeniería de alto rendimiento, absorción de humedad, mala estabilidad dimensional de los productos, resistencia y dureza del metal. Para superar estas deficiencias, ya en la década de 1970, la gente usaba fibra de carbono y fibra de vidrio para mejorar su rendimiento. PA66 reforzado con materiales de fibra de carbono en los últimos años el desarrollo es más rápido, porque PA66 y la fibra de carbono tienen un excelente rendimiento en el campo de los materiales plásticos de ingeniería, el material compuesto encarna la superioridad de los dos, como la resistencia y la rigidez, que el PA66 no mejorado es mucho más alto que el de la fluencia de alta temperatura es pequeño, la estabilidad térmica de una mejora significativa en la precisión dimensional de la buena, resistente al desgaste. En la actualidad, los materiales compuestos de fibra de carbono PA66 son principalmente partículas reforzadas con fibra de carbono cortas o largas y se han utilizado ampliamente en la industria automotriz, artículos deportivos, maquinaria textil, materiales aeroespaciales y otros campos. La fibra de carbono es liviana, tiene alta resistencia a la tracción, resistencia a la abrasión, resistencia a la corrosión, resistencia a la fluencia, conductividad eléctrica, transferencia de calor, etc. Es muy similar a la fibra de vidrio, pero superior a la fibra de vidrio. En comparación con la fibra de vidrio, el módulo es 3 veces mayor, que es un material con alta rigidez y alta resistencia. Hoja de datos de PA6-LCF como referencia A partir de los experimentos del departamento técnico, sabemos que la resistencia a la flexión, el módulo de elasticidad de flexión, la resistencia al impacto y la resistencia al corte plano del material de fibra de carbono PA66 con fibra añadida aumentan con el aumento del contenido de fibra de carbono, la resistencia al corte transversal disminuyó ligeramente. En general, la resistencia del material ha aumentado drásticamente. Aplicación de PA66-LCF Certificado Certificación del Sistema de Gestión de Calidad ISO9001/16949 Certificado de Acreditación de Laboratorio Nacional Empresa de innovación en plásticos modificados Certificado honorario Pruebas REACH y ROHS de metales pesados Fábrica y laboratorio Preguntas y respuestas 1. ¿Existen datos de referencia unificados para el rendimiento de los productos de fibra de carbono? El rendimiento de filamentos de fibra de carbono específicos es fijo, como los filamentos de fibra de carbono de Toray, T300, T300J, T400, T700, etc., se pueden rastrear una serie de parámetros. Sin embargo, no existe un estándar uniforme para medir los productos compuestos de fibra de carbono. En primer lugar, los diferentes tipos de materias primas seleccionadas conducirán a un rendimiento diferente de los productos y luego, debido a la elección de la matriz y al diseño diferente de los productos, conducirán a un rendimiento diferente de los productos. Además de algunos tubos de fibra de carbono comunes, tableros de fibra de carbono y otras piezas convencionales, la mayoría de los productos de fibra de carbono en la producción de la muestra antes de la prueba para determinar si el rendimiento del producto está en línea con el uso del estándar esperado. , y como punto base, para realizar la producción y utilización en grandes cantidades. 2. ¿Son caros los productos compuestos de fibra de carbono? El precio de los productos compuestos de fibra de carbono está estrechamente relacionado con el precio de las materias primas, el nivel de tecnología y la cantidad de productos. Algunos productos de los requisitos del entorno industrial son altos, el rendimiento de los productos y materiales de fibra de carbono tiene requisitos especiales, lo que requiere la selección de materias primas específicas, materias primas, cuanto mayor sea el rendimiento del precio natural, más caro, como el Aplicación de materiales termoplásticos ortopédicos de fibra de carbono PEEK. Por supuesto, cuanto más complejo es el proceso de producción, mayor es el tiempo y la carga de trabajo, y aumenta el coste de producción. Sin embargo, cuanto mayor sea la cantidad del pedido, menor será el costo por pieza, una vez que se haya establecido la producc...ver más

-

Xiamen LFT Poliamida 66 Materiales compuestos de fibra de carbono larga PA66 de alto rendimiento para campos aeroespaciales¿Qué es el plástico PA66? La poliadipiladipilendiamina, comúnmente conocida como nailon -66, es una resina termoplástica, generalmente hecha de condensación de ácido adipónico y hexadipamina. Insoluble en disolventes generales, sólo soluble en m-cresol, etc. Alta resistencia mecánica y dureza, rigidez. Se puede utilizar como plásticos de ingeniería, accesorios mecánicos como engranajes, cojinetes lubricantes, en lugar de materiales metálicos no ferrosos para fabricar carcasas de máquinas, palas de motores de automóviles y también se puede utilizar para fabricar fibras sintéticas. La materia prima plástica PA66 es un polímero cristalino opalescente translúcido u opaco, con plasticidad. Densidad 1,15g/cm3. Punto de fusión 252 ℃. Temperatura de fragilidad -30 ℃. La temperatura de descomposición térmica es superior a 350 ℃. Resistencia al calor continua 80-120 ℃, tasa equilibrada de absorción de agua del 2,5%. Resistente a ácidos, álcalis, la mayoría de las sales inorgánicas acuosas, haluros de alquilo, hidrocarburos, ésteres, cetonas y otras corrosión, pero fácil al fenol, ácido fórmico y otros disolventes polares. Tiene excelente resistencia al desgaste, autolubricidad y alta resistencia mecánica. Pero la absorción de agua es mayor, por lo que la estabilidad dimensional es pobre. ¿Qué es la fibra de carbono larga? En la industria de los plásticos de ingeniería modificados, el material compuesto reforzado con fibra larga se refiere a fibra de carbono larga, fibra de vidrio larga, fibra de aramida o fibra de basalto y matriz polimérica, a través de una serie de métodos de modificación especiales para producir materiales compuestos. La característica más importante de los compuestos de fibras largas es que tienen propiedades superiores que los materiales originales no tienen. Si se clasifican según la longitud de los materiales de refuerzo añadidos, se pueden dividir en compuestos de fibra larga, fibra corta y fibra continua. Como se mencionó al principio, el material compuesto de fibra de carbono larga es un tipo de material compuesto reforzado con fibra larga, que es un nuevo material de fibra con fibra de alta resistencia y alto módulo. El compuesto de fibra de carbono LCF exhibe una alta resistencia a lo largo del eje de la fibra y tiene las características de alta resistencia y peso ligero. Tiene propiedades mecánicas integrales como densidad, resistencia específica y módulo específico que son incomparables con otros materiales. Es un material nuevo con excelentes propiedades mecánicas y muchas funciones especiales. ¿Cuáles son las propiedades de la fibra de Carbono Larga? Resistencia a la corrosión: el material compuesto de fibra de carbono LCF tiene buena resistencia a la corrosión y puede adaptarse a entornos de trabajo hostiles; Resistencia a los rayos UV: gran capacidad para resistir los rayos UV, los productos con problemas de daño por rayos UV son pequeños; Resistencia al desgaste y resistencia al impacto: en comparación con el material general, la ventaja es más obvia; Baja densidad: menor que la densidad de muchos materiales metálicos, puede lograr el propósito de ser liviano; Otras propiedades: como reducir la deformación, mejorar la rigidez, modificar el impacto, aumentar la tenacidad, la conductividad eléctrica, etc. En comparación con la fibra de vidrio, el compuesto de fibra de carbono LCF tiene mayor resistencia, mayor rigidez, menor peso y excelente conductividad eléctrica. ¿Cuáles son los archivos de solicitud de PA66-LCF? 1. Industria militar El compuesto de fibra de carbono larga LFT tiene una resistencia y rigidez específicas muy altas y tiene las características de resistencia a la corrosión, resistencia a la fatiga, resistencia a altas temperaturas y bajo coeficiente de expansión térmica, etc. El compuesto de fibra de carbono LCF se usa ampliamente en cohetes, misiles, aviones militares, protección personal y otros campos militares en el país y en el extranjero. En comparación con los materiales convencionales, los compuestos largos de fibra de carbono permiten mejoras continuas en el rendimiento de los equipos militares, como reducir el peso de los buques de guerra entre un 20 y un 40 por ciento. Al mismo tiempo, el material compuesto de fibra de carbono LCF puede superar el material metálico que es fácil de corroer, fácil de fatigar y otras deficiencias, mejorar y mejorar la durabilidad de los productos militares. Actualmente, más del 40 por ciento de los materiales compuestos de fibra de carbono LCF se utilizan en algunos helicópteros militares avanzados, y aún más en vehículos aéreos no tripulados. Además de los aviones, los buques de guerra marinos también aparecen en una figura de material compuesto de fibra de carbono larga, porque el material compuesto de fibra de carbono larga puede resistir la corrosión del agua de mar y una variedad de impurezas químicas, tiene una larga vida útil, es más duradero que los buques de guerra de acero y tiene menores costos de mantenimient...

- Marca LFT-G

- poliadipiladipdiamina

- material compuesto

- resina termoplástica

- Fibra sintética

- En lugar de material de medalla

Etiquetas :

-

Material compuesto de poliamida 66 Xiamen LFT-G que rellena pellets largos reforzados con fibra de carbono para el sector aeroespacialNúmero de producto: PA66-NA-LCF50 Especificación de fibra: 20%-60% Característica del producto: Alta tenacidad, Peso ligero, Alta resistencia, Resistencia al desgaste, Resistencia a la corrosión, Resistencia a la fluencia, Conducción, Transferencia de calor Aplicación del producto: ala de avión, ala de pato, ala estable, góndola y otros campos aeroespaciales.ver más

correo electrónico

correo electrónico español

español English

English français

français Deutsch

Deutsch русский

русский italiano

italiano português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文