Grado del producto: Grado general

Especificación de fibra: 20% -60%

Característica del producto: alta tenacidad, baja deformación

Aplicación del producto: aparatos electrónicos, piezas de maquinaria, etc.

Grado del producto: Grado general

Especificación de fibra: 20% -60%

Característica del producto: alta tenacidad, baja deformación

Aplicación del producto: aparatos electrónicos, piezas de maquinaria, etc.

Artículo No.:

PBT-NA-LGFPago:

T/T or L/C (other payment ways also can be diorigen del producto:

Xiamen, ChinaColor:

Original color (also can be customized)Puerto de embarque:

Xiamen, ChinaInformación del Producto

El tereftalato de polibutileno (PBT) es un poliéster termoplástico y uno de los cinco plásticos de ingeniería.

PBT tiene un excelente rendimiento integral, es uno de los plásticos de ingeniería más duros y tiene una alta estabilidad dimensional, buena resistencia a la corrosión química, excelente aislamiento eléctrico, buenas propiedades mecánicas y elasticidad, baja absorción de agua, etc.

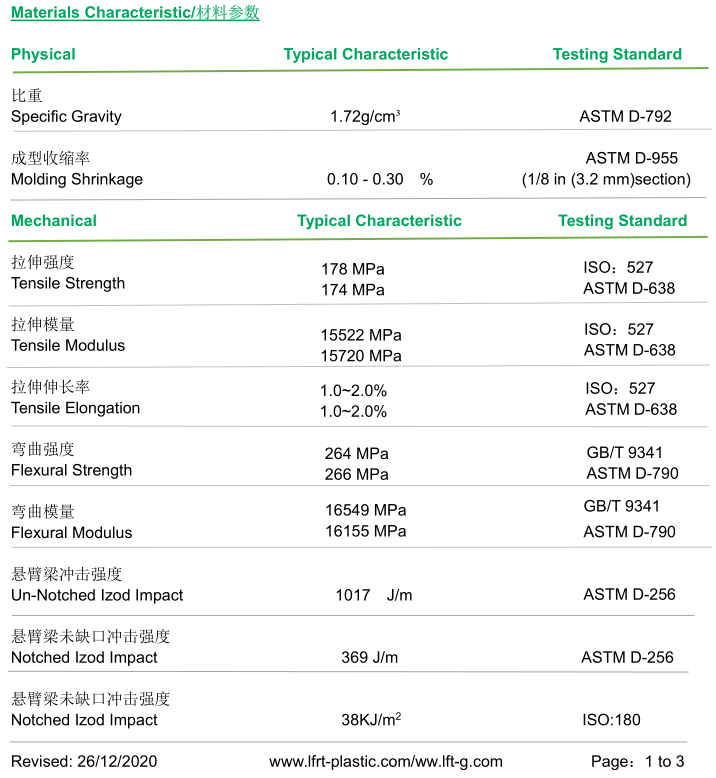

Hoja de datos del producto

(1) Excellent mechanical properties, high strength and fatigue resistance, good dimensional stability, small creep. Under high temperature conditions, the performance changes less.

(2) Easy to flame retardant, has a good affinity with flame retardant, easy to develop additive and reactive flame retardant grade, can meet the requirements of UL94 V-0. It has been widely used in electronic and electrical industry.

(3) Heat resistance, aging resistance, organic solvent resistance. After the enhancement, the UL temperature index is maintained in the range of 120℃ to 140℃, and all have good outdoor long-term aging.

(4) Good processing performance. Easy secondary processing and molding processing, with the help of ordinary equipment can be extruded molding or injection molding; With fast crystallization speed and good fluidity, mold temperature is relatively low

The datasheet is tested by our own lab, for reference only.

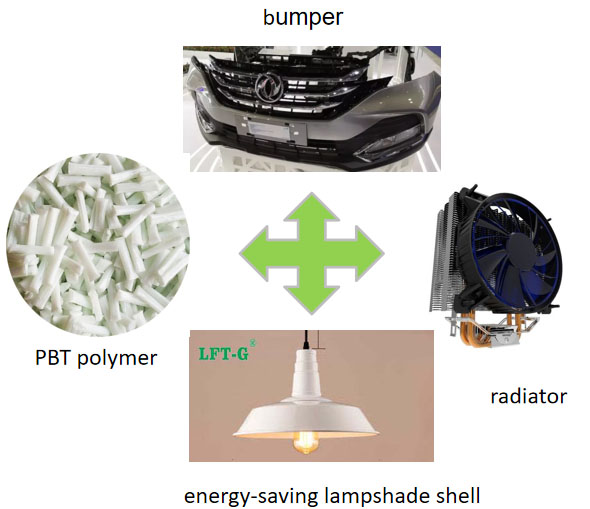

Product application

1. Electronic appliances

No fuse breaker, electromagnetic switch, return transformer, household appliance handle, connector, etc. PBT usually add 30% glass fiber mixed as a connector, PBT is widely used because of its mechanical properties, solvent resistance, good formability and low price.

2. Cooling fan

Glass fiber reinforced PBT is mainly used in the heat dissipation fan, the heat dissipation fan is placed in the machine for a long time to help heat dissipation, the physical properties of plastic requirements have heat resistance, flame resistance, insulation and mechanical strength, PBT is usually in the form of fiber 30% applied as the heat dissipation fan outside the frame and the fan blade coil shaft.

3. Electrical components

Glass fiber reinforced PBT is also used as a transformer, relay in the coil shaft, generally PBT plus fiber 30% injection forming. The required physical properties of coil shaft include insulation, heat resistance, tin resistance, fluidity and strength, etc. The applicable materials include glass fiber reinforced PBT, glass fiber reinforced PA6 and glass fiber reinforced PA66.

4. Automotive

a, external parts: mainly car bumper (PC/PBT), door handle, corner gesson, engine heat hole cover, window motor housing, fender, wire shield, wheel cover, car transmission gear box, etc.;

b. Internal components: mainly include endoscope brace, wiper bracket and control system valve;

c, automotive electrical parts: automotive ignition coil coil and various electrical connectors, etc.

At the same time, it can also be used in the charging gun housing of new energy vehicles.

5. Mechanical equipment

PBT material is also widely used in video tape recorder belt drive shaft, computer cover, mercury lampshade, iron cover, baking machine parts and a large number of gears, cams, buttons, electronic watch housing, camera parts (heat resistant, flame retardant requirements)

About us

Xiamen LFT composite Plastic Co., LTD., especializada en la modificación de plásticos de ingeniería durante 20 años. Nuevos materiales, nueva tecnología, cuidadosamente hacer cada material. Nuestra empresa puede personalizar los materiales según las necesidades del cliente. Con más de 20 años de acumulación de experiencia técnica, somos un fabricante confiable de materiales modificados. ¡Bienvenido a consultar, podemos brindarle soluciones personalizadas, cotizaciones gratis!

Correo electrónico: sale02@lfrtplastic.com

Número de contacto: 13950095727