-

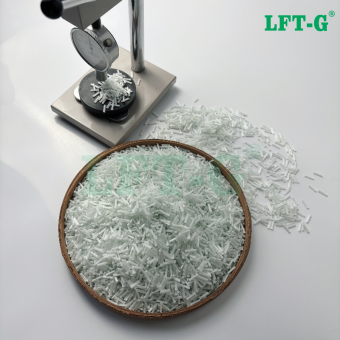

LFT-G Poliamida 6 nailon 6 relleno fibra de vidrio larga color original para piezas de automociónLas principales ventajas de nailon 6 son sus rigidez y resistencia a la abrasión Además, este material tiene Excelente resistencia al impacto , resistencia al desgaste , y propiedades aislantes eléctricas El nailon 6 es un altamente elástico y material resistente a la fatiga , lo que significa que recuperará sus proporciones originales tras ser deformado por la tensión. Esta poliamida no es tóxica y puede combinarse con fibras de vidrio o carbono para aumentar su rendimiento.

- Propiedades del compuesto de poliamida 6

- Resina termoplástica lgf a buen precio

- PA6 de alto impacto en lugar de plástico metálico

- Filtro GF30 de plástico moldeado por inyección

- Relleno de fibra de vidrio larga PA6 personalizado

- Compuestos ligeros de plástico reforzado

Etiquetas :

-

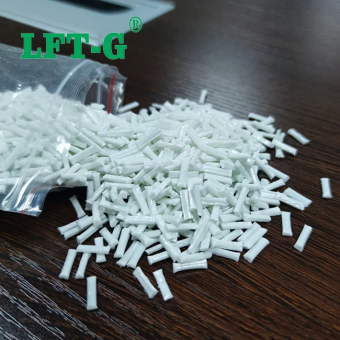

Pellets reforzados con nailon PA6 de fibra de carbonoNailon 6 es un material adecuado para moldeo por inyección Las piezas de nailon moldeadas resultantes poseen gran resistencia, así como resistencia química y térmica. Al moldear nailon 6, a veces se inyecta una cantidad específica de... fibras de vidrio o de carbono (generalmente entre 20% y 60% ) para aumentar su resistencia a la tracción.

- compuesto de pulido de fibra de carbono

- pellets de carbón

- nailon 6 de poliamida

- densidad de poliamida 6

- nailon 6 poliamida

- pellets de carbón activado

Etiquetas :

-

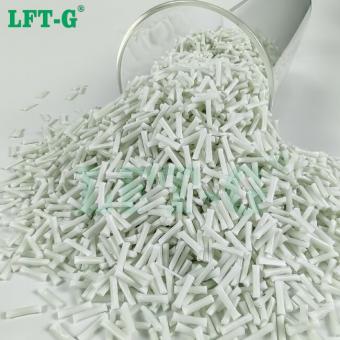

LFT-G PA6 Poliamida6 nailon6 relleno fibra de vidrio larga 40 color original para piezas de automociónNailon reforzado con fibra de vidrio larga PA6 y PA6-LGF PA6, also known as Nylon 6, is a high-performance polyamide widely used in engineering plastics, fibers, and films. It is a thermoplastic polymer with repeating amide groups (-NH-CO-) in the main chain, offering strong mechanical properties and versatile processing capabilities. What is PA6 Plastic? PA6 is an aliphatic polyamide that provides excellent strength, wear resistance, and chemical resistance to weak acids, alkalis, and certain organic solvents. Its lightweight and processable nature make it widely applied in fibers, engineering plastics, and thin films. However, the polar amide groups in PA6 easily form hydrogen bonds with water molecules, which can result in high moisture absorption, dimensional changes, and reduced impact strength in dry or low-temperature conditions. Advantages of PA6 High mechanical strength and toughness with excellent tensile and compressive properties Outstanding fatigue resistance, maintaining strength after repeated bending High softening point, heat resistant Low friction and wear-resistant surface Corrosion resistance to alkalis, salts, weak acids, oils, and most solvents Self-extinguishing, non-toxic, odorless, and good weather and biological resistance Excellent electrical insulation even in high humidity environments Lightweight, easy to dye, and easy to mold due to low melting viscosity Limitations of PA6 High moisture absorption (up to 3% when saturated) Poor light and thermal stability; prolonged high-temperature exposure may cause discoloration and surface cracking Strict injection molding requirements; trace moisture can affect product quality Dimensional stability is sensitive to thermal expansion and wall thickness variations Not resistant to strong acids or oxidizing agents; unsuitable for acid-resistant applications Why Reinforce PA6 with Long Glass Fiber? To overcome the natural limitations of PA6, long glass fiber (LGF) reinforcement is applied. PA6-LGF composites combine the lightweight, chemical, and heat resistance of PA6 with the mechanical strength and dimensional stability of long glass fibers. LGF reinforcement improves tensile, compressive, and flexural strength, reduces shrinkage, enhances fatigue resistance, and provides improved thermal and chemical stability. This makes PA6-LGF ideal for high-performance structural components. Applications of PA6-LGF PA6 reinforced with 30% long glass fiber (30% LGF) is widely used in: Power tool shells and components Engineering machinery parts Automobile structural and functional components The composite improves mechanical strength, dimensional stability, heat resistance, aging resistance, and fatigue resistance. Its fatigue strength can be up to 2.5x that of unreinforced PA6. Processing and Forming Tips for 30% PA6-LGF Shrinkage is reduced to ~0.3% compared with 1–1.5% for pure PA6. Excessive fiber content may cause surface floating fibers and poor compatibility. 30% LGF is recommended for balanced performance. Recycled material content should be kept below 25% to avoid color and mechanical property degradation. Gradual cooling after molding prevents warping due to fiber orientation during injection molding. Mold design, gate position, and temperature control are critical. Customers & Staffs Certificates

- Compuesto de poliamida 6

- resina termoplástica lgf

- PA6 de alto impacto

- plástico moldeado por inyección

- relleno de fibra de vidrio larga pa6

- Plástico reforzado

Etiquetas :

-

Compuestos de fibra de carbono larga rellenos de resina termoplástica de nailon 6,6 LFT-GEl material de nailon 66 para mecanizado tiene una resistencia a la temperatura mejorada y menores tasas de absorción de agua en comparación con el nailon 6 estándar.

- Compuestos de fibra de carbono PA66

- Materiales estructurales ligeros

- Poliamida 66 de alta resistencia

- Compuestos de fibra de carbono para automoción

- Durabilidad del nailon reforzado con fibra de carbono

- Compuestos termoplásticos avanzados

Etiquetas :

correo electrónico

correo electrónico español

español English

English français

français Deutsch

Deutsch русский

русский italiano

italiano português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文