Artículo No.:

PP-NA-LGF20Pago:

T/T or L/C (other payment ways also can be diorigen del producto:

Xiamen, ChinaColor:

Original color (also can be customized)Puerto de embarque:

Xiamen, China¿Qué es la fibra de vidrio larga?

El plástico reforzado con fibra de vidrio larga se basa en el plástico puro original, agregando fibra de vidrio larga y otros aditivos, para mejorar el alcance del uso de los materiales.

¿Por qué llenar Fibra de Vidrio Larga?

1. Después del refuerzo de fibra de vidrio larga, la fibra de vidrio larga es un material resistente a altas temperaturas, por lo tanto, la temperatura de resistencia al calor de los plásticos reforzados es mucho más alta que antes sin fibra de vidrio larga, especialmente plásticos de nailon;

2. Después del refuerzo de fibra de vidrio larga, debido a la adición de fibra de vidrio larga, se limitó el movimiento mutuo entre las cadenas de polímeros de plásticos, por lo tanto, la tasa de contracción de los plásticos reforzados disminuye mucho, la rigidez mejora considerablemente;

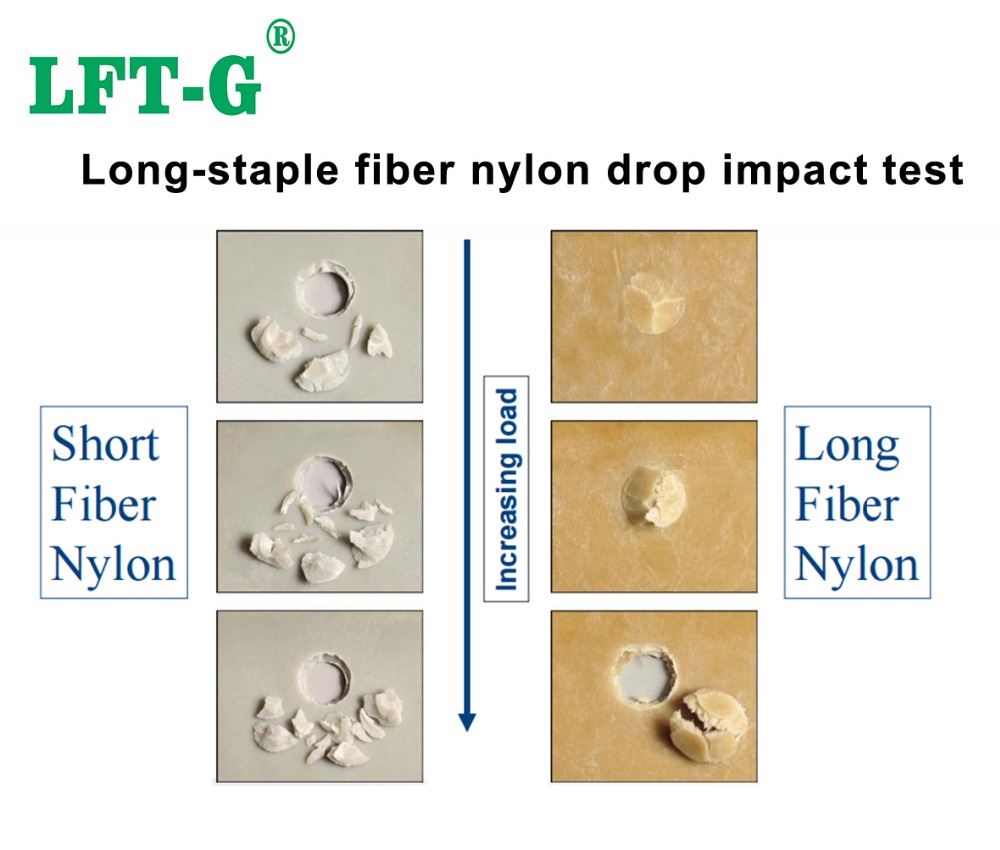

3. Después de un refuerzo largo de fibra de vidrio, el plástico reforzado no se agrietará por tensión, al mismo tiempo, el rendimiento anti-impacto del plástico mejora mucho;

4. After long glass fiber reinforcement, long glass fiber is a high strength material, which also greatly improves the strength of plastic, such as: tensile strength, compression strength, bending strength, improve a lot;

5. Long glass fiber reinforced after, due to the addition of long glass fiber and other additives, the combustion performance of reinforced plastics decreased a lot, most of the material can not ignite, is a kind of flame retardant material.

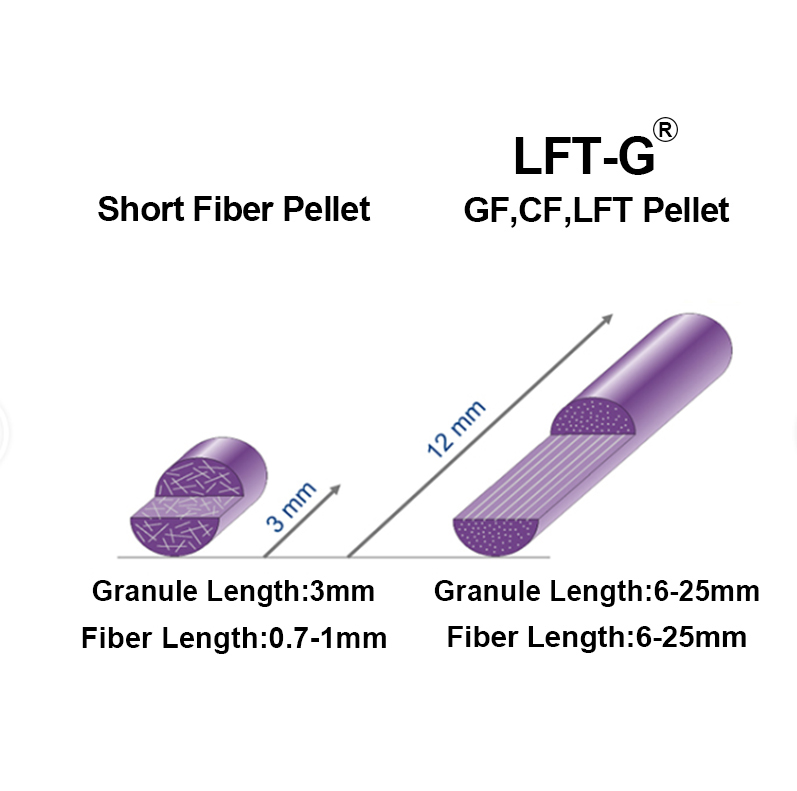

Why choose Long Glass Fiber instead of Short Glass Fiber?

Compared with short fiber reinforced thermoplastic composites, LFT has the following advantages:

• Long fiber length, significantly improve the mechanical properties of products.

• High specific stiffness and strength, good impact resistance, especially suitable for automotive applications.

• Improved creep resistance, good dimensional stability, high parts forming accuracy.

• Excellent fatigue resistance.

• Better stability in hot and humid environments.

• The fiber can move relatively in the molding mold during the molding process, and the fiber damage is small.

Appearance of PP-LGF

Application of PP-LGF

Automotive parts

Front end module, door module, shift mechanism, electronic accelerator pedal, dashboard skeleton, cooling fan and frame, battery carrier, bumper bracket, underbody protection plate, sunroof frame, etc., used to replace reinforced PA or metal materials.

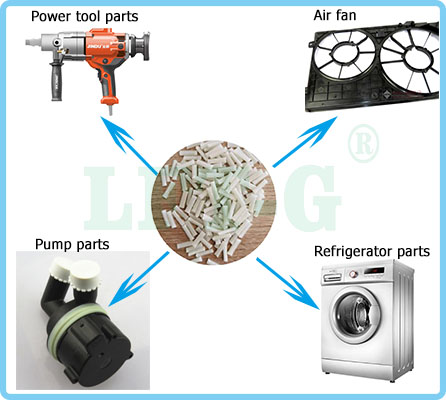

Household appliance

Washing machine drum, washing machine triangle bracket, one brush machine drum, air conditioning fan, etc., used to replace short glass fiber reinforced PA, APS metal materials.

Communications, electronics, electrical appliances

High-precision connectors, igniter components, coil shaft, relay base, microwave oven transformer coil frame/frame, electrical connector, solenoid valve package, scanner components, etc.

Others

Power tool housing, water pump or water meter housing, impeller, bicycle skeleton, skis, ground locomotive pedals, military/civil safety helmets, safety shoes, etc. are used to replace short glass fiber reinforced PA, PPO, etc.

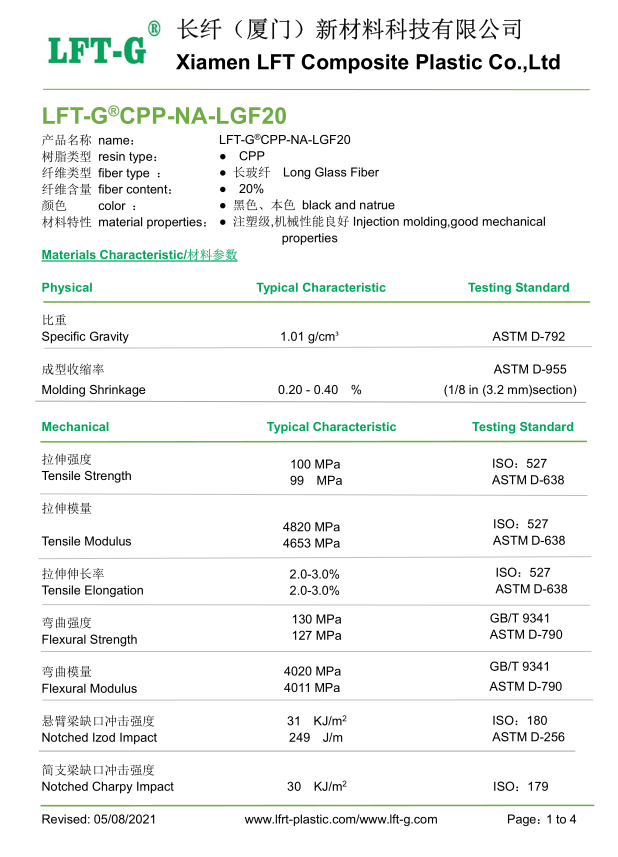

TDS for reference

About us

Xiamen LFT composite plastic Co., Ltd. is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm length. The company's long-fiber continuous infiltration reinforced thermoplastics have passed ISO9001 &16949 system certification, and the products have obtained lots of national trademarks and patents.

We will offer you:

1. LFT&LFRT material technical parameters and leading edge design;

2. Mold front design and recommendations;

3. Provide technical support such as injection molding and extrusion molding.