PPS-LGF

The resin matrix of long fiber reinforced thermoplastic composites involves general and special engineering plastics. Xiamen Long Fiber has been focusing on the field of LFT for more than ten years, with a complete variety, including PP, PA, MXD6, PPA, PC, PBT, TPU, PPS, PEEK, etc. PPS is a kind of thermoplastic special engineering plastics with excellent comprehensive performance, and is a typical representative of special engineering plastics, commonly known as "plastic gold".

PPS has excellent high temperature resistance, corrosion resistance, radiation resistance, flame retardant, balanced physical and mechanical properties, excellent dimensional stability and excellent electrical properties. Compared with other high performance thermoplastic engineering plastics PPS has the characteristics of easy processing, low cost and good adhesion with other materials, so it becomes an excellent resin matrix for manufacturing composite materials.

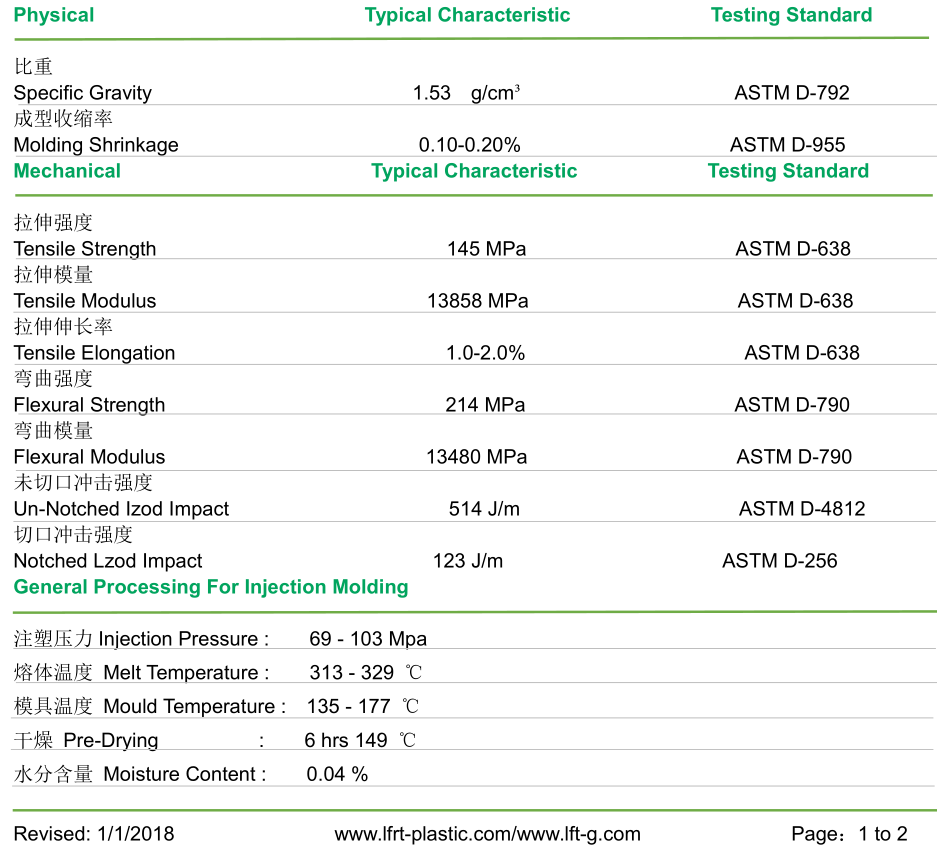

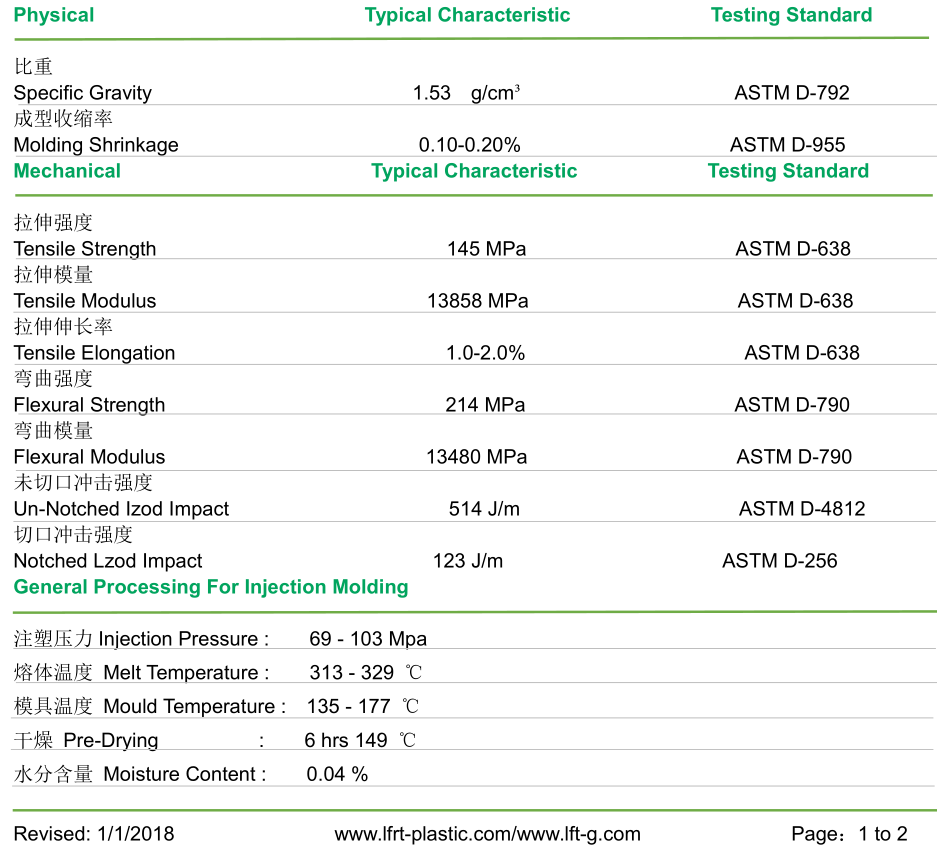

Performance

PPS material although has many advantages, but the pure PPS material is not only brittle, impact resistance is poor, and the processing is difficult, expensive. In order to improve these defects, we need to modify the PPS material. The modified PPS material can improve its thermal conductivity, wear resistance and high temperature resistance.

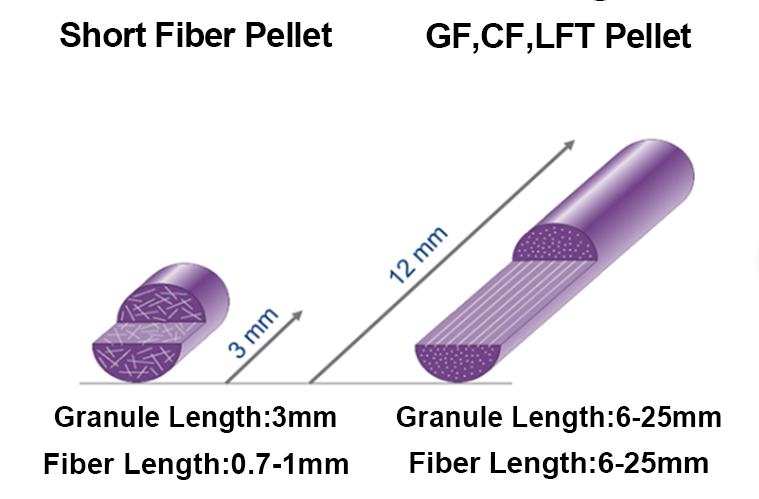

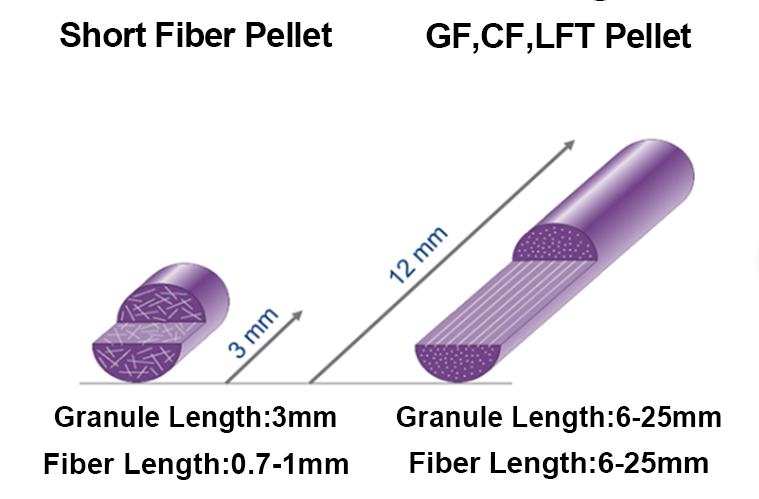

Compare with Short Glass Fiber

The reinforcement fibers added in the resin matrix can form a supporting skeleton, and the reinforcement fibers can effectively bear the external load when subjected to external force. At the same time, energy can be absorbed by fracture, deformation and other ways to improve the mechanical properties of resin.

Therefore, increasing the amount of glass fiber, its tensile strength and bending strength are gradually increased. The tensile and bending properties of PPS/LGF composites are higher than those of PPS/SGF composites. The tensile strength, bending strength and bending elastic modulus of PPS/LGF composites are increased by 11.0%, 18.9% and 11.3% compared with PPS/SGF composites, respectively. PPS/LGF composites have higher length retention rate of glass fiber. Under the condition of the same glass fiber content, the composites have stronger load resistance and better mechanical properties.

The impact performance of long glass fiber composites is 3-5 times stronger than that of short glass fiber composites. Moreover, with the increase of the glass fiber content, the glass fiber in the composite can form an effective spatial network, and the reinforcement effect is greater than that of the glass fiber tip. Under the action of external load, the external load can be transferred to the reinforced fiber better, thus improving the overall performance of the composite. In the PPS/LGF system, the glass fiber length is longer and the spatial network is more dense. The reinforced glass fiber has greater bearing capacity and better impact strength.

The introduction of glass fiber greatly improves the heat resistance of composite materials. The main reason is that the glass fiber forms a network skeleton of reinforced fiber inside the composite material, which greatly improves its heat resistance. The longer size of the glass fiber in PPS/LGF makes the heat resistance improvement more obvious.

With the increase of glass fiber content, the construction of reinforced fiber network inside the composite becomes more perfect. This is also the main reason that the overall mechanical properties of composites increase with the increase of glass fiber content. Compared with PPS/SGF and PPS/LGF composites, the glass fiber retention rate of PPS/LGF composites is higher, which is also the main reason for the better mechanical properties of PPS/LGF composites.

En conclusión, las propiedades mecánicas de PPS/LGF se mejoran entre 2 y 5 veces en comparación con los materiales de PPS/SGF. La resistencia a la tracción, la resistencia a la flexión, el módulo de elasticidad a la flexión, la resistencia al impacto con muescas y la resistencia al impacto sin muescas mejoran en comparación con los materiales PPS/SGF.

Solicitud

Adecuado para muchos campos:

Impulsor de calentador de agua/carcasa de bomba/junta/válvula, impulsor de bomba química/carcasa, impulsor de agua de refrigeración/carcasa, piezas de electrodomésticos

Proporciónenos la imagen del producto, le ayudaremos a evaluar si el material se puede utilizar.

Bandeja de alta temperatura

Mostrar

Sobre nosotros

Xiamen LFT composite plastic Co., Ltd. es una empresa de marca que se enfoca en LFT y LFRT. Serie de fibra de vidrio larga (LGF) y fibra de carbono larga (LCF). El termoplástico LFT de la compañía se puede usar para moldeo por inyección y extrusión LFT-G, y también se puede usar para moldeo LFT-D. Se puede producir de acuerdo con los requisitos del cliente: 5 ~ 25 mm de longitud.

Los termoplásticos reforzados con infiltración continua de fibra larga de la compañía han pasado la certificación del sistema ISO9001 y 16949, y los productos han obtenido muchas marcas comerciales y patentes nacionales.

correo electrónico

correo electrónico español

español English

English français

français Deutsch

Deutsch русский

русский italiano

italiano português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文