-

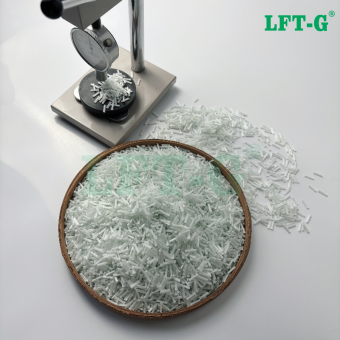

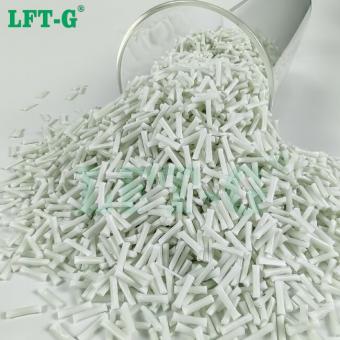

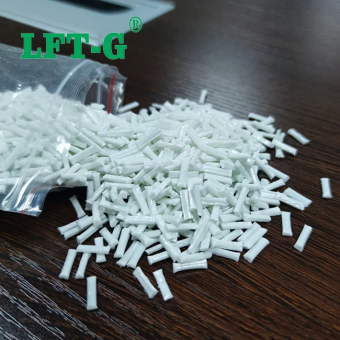

Muestra disponible de 12 mm de resistencia de alta tenacidad de plástico modificado con fibra de carbono larga LFT-D PA6¿Qué es PA6? Nylon6 (PA6), también conocido como poliamida 6, nombre en inglés: Polyamide6 o Nylon6, PA6 para abreviar; Es decir, policaprolactama, obtenida por policondensación por apertura de anillo de caprolactama. Es una resina opalescente translúcida u opaca, con propiedades mecánicas superiores, rigidez, tenacidad, resistencia al desgaste y absorción de impactos mecánicos, buen aislamiento y resistencia química. Ampliamente utilizado en piezas de automóviles, piezas electrónicas y eléctricas y otros campos. ¿ Cuáles son las ventajas y desventajas de PA6? Principales ventajas de PA: 1. Alta resistencia mecánica, buena tenacidad, alta resistencia a la tracción ya la compresión. 2. excelente resistencia a la fatiga, las piezas después de doblarse repetidamente aún pueden mantener la resistencia mecánica original. 3. alto punto de reblandecimiento, resistente al calor. 4. superficie lisa, pequeño coeficiente de fricción, resistente al desgaste. 5. Resistencia a la corrosión, muy alcalina y la mayoría de las sales, también resistentes a ácidos débiles, aceite, gasolina, compuestos aromáticos y solventes generales, los compuestos aromáticos son inertes, pero no resistentes a ácidos fuertes y oxidantes. 6. con autoextinguible, no tóxico, inodoro, buena resistencia a la intemperie. 7. Excellent electrical performance. Good electrical insulation, nylon volume resistance is high, high breakdown voltage resistance, in dry environment, can be used as power frequency insulation material, even in high humidity environment still has good electrical insulation. 8. light weight, easy to dye, easy to form. Main disadvantages of PA: 1. easy to absorb water. High water absorption, saturated water can reach more than 3%. The dimensional stability and electrical properties are affected to some extent, especially the thickening of thin-walled parts. Water absorption also greatly reduces the mechanical strength of plastics. 2. Poor light resistance. In a long-term high temperature environment, it will oxidize with oxygen in the air, turn brown at the beginning, and then break and crack. 3. injection molding technology requirements are more strict: the existence of trace moisture will cause great damage to the quality of molding; The dimensional stability of the product is difficult to control because of thermal expansion. The existence of sharp Angle in the product will lead to stress concentration and reduce the mechanical strength; If the wall thickness is not uniform, it will lead to the distortion and deformation of the parts. High precision of equipment is required in post-processing. 4. will absorb water, alcohol and swelling, not resistant to strong acid and oxidant, can not be used as acid-resistant materials. There are many advantages of PA6, but also many disadvantages, these disadvantages limit the play of the advantages, so people thought of modifying methods to enhance its application. What is the Long Carbon Fiber reinforced PA6? Long carbon fiber reinforced composites offer significant weight savings and provide optimum strength and stiffness properties in reinforced thermoplastics. The excellent mechanical properties of long carbon fiber reinforced composites make it an ideal replacement for metals. Combined with the design and manufacturing advantages of injection molded thermoplastics, long carbon fiber composites simplify the re-imagining of components and equipment with demanding performance requirements. Its widespread use in aerospace and other advanced industries make it a "high-tech" perception of consumers - you can use it to market products and create differentiation from competitors. What is the differences between Long Carbon Fiber and Short Carbon Fiber? Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher (toughness) than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. TDS for reference only Application cases Product details Number Color Length MOQ Sample Package Port of Loading Delivery time PA6-NA-LCF50 Original color or as required About 12mm 20kg Available 20kg/bag Xiamen Port 7-15days after shipment Frequently asked questions 1. The product is easy to brittle, so changing to use long fiber reinforced thermoplastic materials can solve this problem? A: The overall mechanical properties must be improved. The characteristics of long glass fiber and long carbon fiber are the advantages in mechanical properties. It has 1-3 times higher (toughness) than short fiber, and the tensile strength(strength and rigidity) is increased by 0.5-1 times. 2. Are there any special progress requiremets of long carbon fiber injection molding products? A: We must consider the requirements of long carbon fiber for the injection molding machine screw nozzle, mold structure and injection molding process. Long carbon fiber is a relatively high cost materia...

- Material reforzado con poliamida6

- Serie de fibra de carbono de la marca LFT-G

- pa6 compuesto lcf

- Compuesto de nailon6 pa

- Plástico largo relleno de fibra de carbono.

- fibra lcf50

Etiquetas :

correo electrónico

correo electrónico español

español English

English français

français Deutsch

Deutsch русский

русский italiano

italiano português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文