Artículo No.:

PA66-NA-LCF40Pago:

T/T or L/C (other payment ways also can be diorigen del producto:

Xiamen, ChinaColor:

Original color (also can be customized)Puerto de embarque:

Xiamen, ChinaWhat is PA66 plastic?

Polyadipyladipylenediamine, commonly known as nylon -66, is a thermoplastic resin, generally made from adiponic acid and hexadipamine condensation.

Insoluble in general solvents, only soluble in m-cresol, etc.

High mechanical strength and hardness, rigidity.

It can be used as engineering plastics, mechanical accessories such as gears, lubricating bearings, instead of non-ferrous metal materials to make machine shells, automotive engine blades, and can also be used to make synthetic fibers.

PA66 plastic raw material is translucent or opaque opalescent crystalline polymer, with plasticity.

Density 1.15g/cm3. Melting point 252℃. Embrittlement temperature -30℃.

Thermal decomposition temperature is greater than 350℃.

Continuous heat resistance 80-120℃, balanced water absorption rate of 2.5%.

Resistant to acid, alkali, most aqueous inorganic salts, alkyl halides, hydrocarbons, esters, ketones and other corrosion, but easy to phenol, formic acid and other polar solvents.

It has excellent wear resistance, self lubricity and high mechanical strength. But the water absorption is larger, so the dimensional stability is poor.

What is Long Carbon Fiber?

In the modified engineering plastics industry, long fiber reinforced composite material refers to long carbon fiber, long glass fiber, aramid fiber or basalt fiber and polymer matrix, through a series of special modification methods to produce composite materials.

The biggest characteristic of long fiber composites is that they have superior properties that the original materials do not have. If they are classified according to the length of the added reinforcement materials, they can be divided into long fiber, short fiber and continuous fiber composites.

As mentioned in the beginning, long carbon fiber composite material is a kind of long fiber reinforced composite material, which is a new fiber material with high strength and high modulus fiber.

LCF carbon fiber composite exhibits high strength along the fiber axis, and has the characteristics of high strength and light weight. It has the comprehensive mechanical properties such as density, specific strength and specific modulus that are incomparable to other materials. It is a new material with excellent mechanical properties and many special functions.

What are the properties of Long Carbon fiber?

Corrosion resistance: LCF carbon fiber composite material has good corrosion resistance, can adapt to harsh working environment;

Uv resistance: strong ability to resist UV, products by UV damage problem is small;

Wear resistance and impact resistance: compared with the general material advantage is more obvious;

Low density: lower than the density of many metal materials, can achieve the purpose of lightweight;

Other properties: such as reducing warpage, improving rigidity, impact modification, increasing toughness, electrical conductivity and so on.

Compared with glass fiber, LCF carbon fiber composite has higher strength, higher rigidity, lower weight, and excellent electrical conductivity.

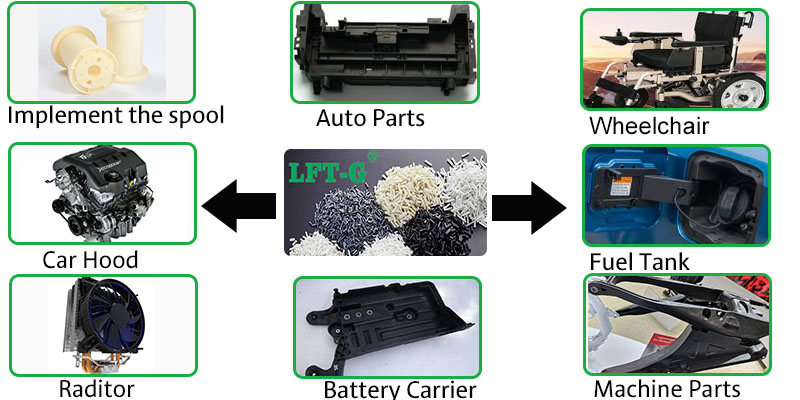

What is the application fileds of PA66-LCF?

1. Military industry

LFT long carbon fiber composite has very high specific strength and stiffness, and has the characteristics of corrosion resistance, fatigue resistance, high temperature resistance and low thermal expansion coefficient, etc. LCF carbon fiber composite is widely used in rocket, missile, military aircraft, personal protection and other military fields at home and abroad. Compared with conventional materials, long carbon fiber composites allow for continuous improvements in the performance of military equipment, such as reducing the weight of warships by 20 to 40 percent.

At the same time, LCF carbon fiber composite material can overcome the metal material is easy to be corroded, easy to fatigue and other shortcomings, improve and enhance the durability of military products. Currently, more than 40 percent of LCF carbon fiber composite materials are used in some advanced military helicopters, and even more in unmanned aerial vehicles. In addition to aircraft, Marine warships also appear long carbon fiber composite material figure, because long carbon fiber composite material can withstand the corrosion of seawater and a variety of chemical impurities, has a long service life, more durable than steel warships, lower maintenance costs, has become an important strategic material for the development of modern defense military weapons and equipment.

2. Home appliance field

LCF carbon fiber composite material has low density, good chemical resistance, excellent performance and other characteristics, has gradually become the home appliance industry's preferred modified engineering plastics, its usage accounts for about 30% and is on the rise. Moreover, home appliances are more and more intelligent and personalized, and the modified performance requirements of materials are higher. So it's no surprise that long carbon fiber composites are chosen by the home appliance industry.

1, green and environmental protection: compared with traditional materials, the production process is relatively simple, but also more environmental protection, more economic, and has high gloss, easy to form, scratch resistance, recyclable characteristics;

2, safety and high stability: has good size stability, can adapt to low and high temperature use environment, deformation problem is small, the use of safety;

3, high fatigue resistance: can be used for a long time, with small creep, excellent comprehensive mechanical properties;

4. Lightweight: Low density makes the weight of the finished product lighter and convenient for daily use.

3. Wind turbine blade

One of the key components of wind turbine is the blade. The production of wind turbine blade should take into account the aerodynamic influence, technical process and composite material structure, and the blade length is proportional to the power of wind turbine. Although the overall mass of the blade is not large, it is the highest cost component in the fan, accounting for 15%-20%, so the selection of materials for making the blade is very important.

The fan blade is not easy to be affected by surface pollutants and roughness, and the thicker blade shape should be used as far as possible in structure. The higher the number of anti-fatigue times it can withstand the wind, the better. With the increase of blade length, new requirements are put forward for the strength and stiffness of reinforcement materials. The performance of glass fiber in the manufacture of large composite blades is obviously insufficient. Using LFT long carbon fiber composite is the best way to reduce the mass requirement of blades and meet the strength and stiffness requirements.

In the development of more powerful wind power installations and longer rotor blades, the use of LCF carbon fiber composite materials with better performance is the general trend. Moreover, with a certain amount of support, long carbon fiber blades are cheaper than glass fiber blades, and material consumption, labor, transportation and installation costs will be reduced.

4. Commodity industry

Skateboard is a kind of easy wear items, and in the sliding process, both ends are vulnerable to impact, friction, cracking, after a long time of use impact prone to plate damage, cracking, soon scrapped can not be used. The anti-collision head made of LCF carbon fiber composite material can effectively prevent the damage caused by collision at both ends of the skateboard.

5. Medical device industry

Las sillas de ruedas médicas son una herramienta importante para la rehabilitación. Proporcionan servicios de movilidad para personas con movilidad reducida y discapacidades físicas. También hacen posible el ejercicio físico y la participación en actividades sociales. Las sillas de ruedas generalmente constan de cuatro partes: marco de la silla de ruedas, rueda, freno y asiento. La silla de ruedas hecha de material compuesto de fibra de carbono largo LFT se mejora principalmente para mejorar la función y la comodidad del movimiento, mejorar el uso de la comodidad y la longevidad.

Preguntas y respuestas

1. ¿Cuál es la diferencia entre fibra de vidrio y fibra de vidrio?

R. Son iguales.

2. ¿Cuál es el tamaño de la fibra de vidrio?

A. Alrededor de 10 ~ 12 mm de longitud.

3. ¿Qué significa PA66-NA-LCF30?

R. Esto significa relleno de PA66 de grado normal con un 30 % de fibra de carbono larga.

4. ¿Cuál es la diferencia entre fibra de carbono larga y Kevlar?

R. La fibra de aramida y la fibra de carbono son dos formas de fibra sintética. Ambos materiales tienen alta resistencia, pero la principal diferencia es su uso.

Kevlar se usa principalmente en ropa protectora y productos a prueba de balas, mientras que la fibra de carbono es más prolífica en industrias fuera de la industria textil, como la construcción naval y la fabricación aeroespacial.

La NASA ha utilizado Kevlar para fabricar guantes y gorros que mantienen seguros a los astronautas cuando realizan caminatas espaciales en misiones fuera de la atmósfera terrestre, mientras que la fibra de carbono se ha utilizado para hacer que los barcos sean más ligeros y resistentes, entre otros usos.