Artículo No.:

ABS-NA-LGF30Pago:

T/T or L/C (other payment ways also can be diorigen del producto:

Xiamen, ChinaColor:

Original color (also can be customized)Puerto de embarque:

Xiamen, Chinaabdominales

La resina ABS es un material estructural polimérico termoplástico con alta resistencia, buena tenacidad y fácil procesamiento y moldeado.

Gránulos de ABS reforzados con fibra de vidrio larga

After the long glass fiber reinforcement, the burning performance of the reinforced plastic decreases a lot due to the addition of long glass fiber and other additives, and most of the materials cannot be ignited, which is a kind of flame retardant material.

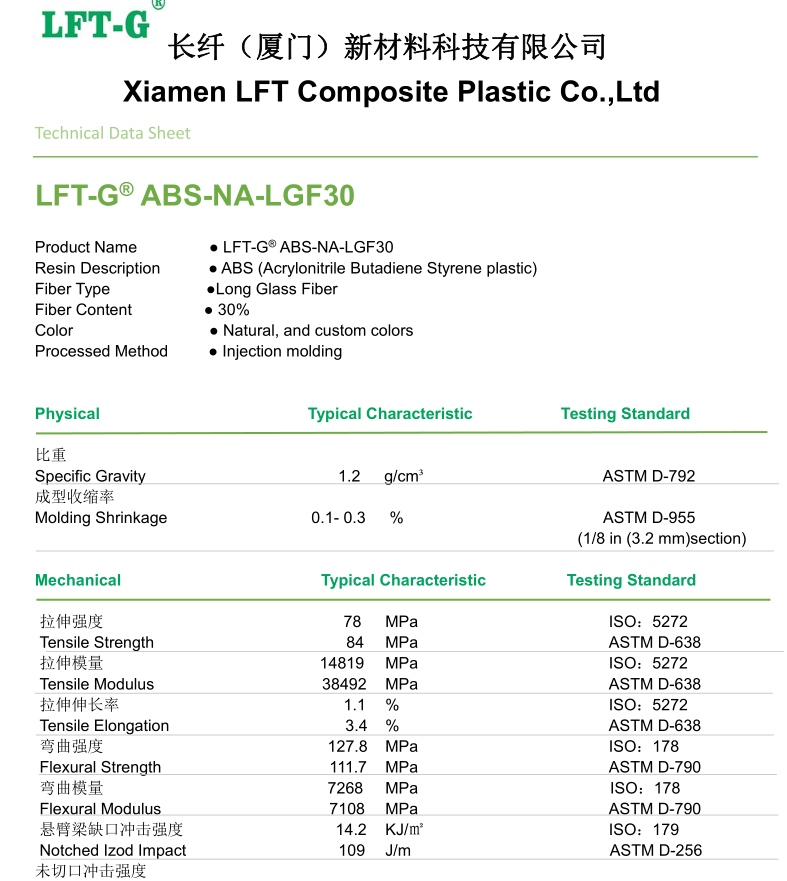

Datasheet for reference

Application

Can be used at many fields.

For more details, please contact us.

Other products you may wonder

PP-NA-LGF PA6-NA-LGF TPU-NA-LGF

Frequently asked questions

Q. What are the differences and advantages of long fiber materials and thermosets and staple fibers?

A. Compared with the short fiber, it has more excellent performance in mechanical properties. It is more suitable for large products and structural parts. It has 1-3 times higher toughness than short fiber, and the tensile strength (strength and rigidity) is increased by 0.5-1 times. Compared with thermosets, it is more environmentally friendly. It can be recycled and reused, and has simple molding efficiency, lower cost etc. But its mechanical properties are worse than thermosets.

Q. Using a long fiber reinforced thermoplastic material, will it block the die hole due to the long length of the fiber or not?

A. When using long glass fiber or long carbon fiber, it is necessary to evaluate whether the product is suitable for LFT-G. If the product is too small or the dispensing is not suitable for long fiber materials. The long fiber itsalf has requirements for the mold nozzle.

Q. How to choose the reinforcement method and length of the material when using long fiber reinforced thermoplastic material?

A. The selection of materials depend on the requirements of the products. It is necessary to assess how much the content is reinforced and how much length is more appropreate, which are depending on the performance requirements of the products.

Xiamen LFT composite plastic Co., Ltd.

We will offer you

1. LFT & LFRT material technical parameters and leading edge design

2. Mold front design and recommendations

3. Provide technical support such as injection molding and extrusion molding