Información del Producto

PA12 es nailon 12, también conocido como polidodecactam, polilauractama, es un nailon de cadena larga de carbono. El material base para su polimerización es el butadieno, un material termoplástico semicristalino-cristalino. El nailon 12 es el nailon de cadena de carbono larga más utilizado, además de la mayoría de las propiedades generales del nailon, baja absorción de agua y tiene una alta estabilidad dimensional, resistencia a altas temperaturas, resistencia a la corrosión, buena tenacidad, fácil procesamiento y otras ventajas. En comparación con PA11, otro material de nailon de cadena larga de carbono, el precio del butadieno, la materia prima de PA12, es solo un tercio del precio del aceite de ricino, la materia prima de PA11. Puede reemplazar PA11 y aplicarse en la mayoría de las escenas, y tiene una amplia gama de aplicaciones en tuberías de combustible de automóviles, mangueras de frenos de aire, cables submarinos, impresión 3D y muchos otros campos.

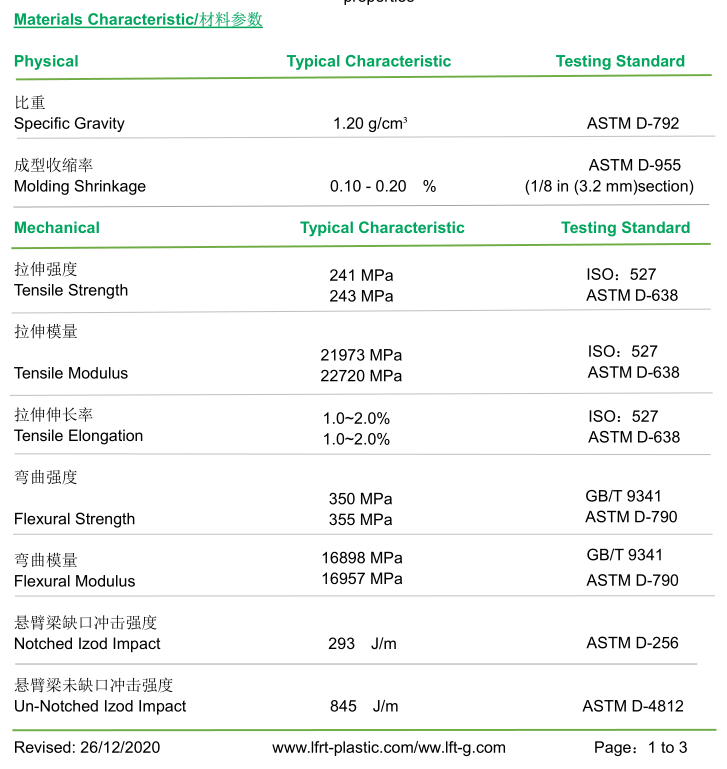

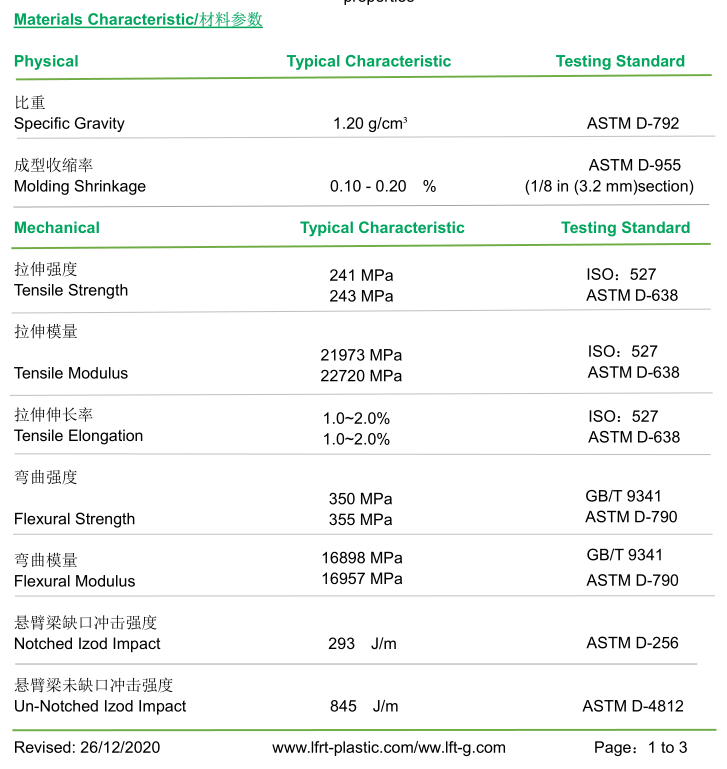

In long chain nylon, compared with other nylon materials, PA12 has great advantages, such as the lowest water absorption rate, the lowest density, low melting point, impact resistance, friction resistance, low temperature resistance, fuel resistance, good dimensional stability, good anti-noise effect. PA12 has the properties of PA6, PA66 and polyolefin (PE, PP) at the same time, achieving the combination of lightweight and physical and chemical properties, and has advantages in performance. The following table shows the performance data:

Product detail

There are a large number of non-polar methylene groups in nylon 12, which makes nylon 12 molecular chain more compliant. The amide group in nylon 12 is polar, and the cohesion energy is very large, it can form hydrogen bonds between the molecules, so that the molecular arrangement is regular. Therefore, nylon 12 has high crystallinity and high strength. Nylon 12 has low water absorption, good low temperature resistance, good air tightness, excellent alkali and oil resistance, medium resistance to alcohol, inorganic dilute acid and aromatic hydrocarbons, good mechanical and electrical properties, and is a self-flameout material.

1) Density

The relative density of nylon 12 is only 1.01-1.03, which is the smallest among all engineering plastics, which has a certain effect on reducing the quality of vehicles and reducing fuel consumption. When compared by unit volume, nylon 12 has advantages in price and performance.

2) Melting point

The melting point of nylon 12 is 172-178℃, slightly lower than nylon 11, can fully meet the requirements of automobile fuel pipe and brake pipe working environment temperature.

3) Water absorption

As we all know, the biggest disadvantage of nylon products is large water absorption, dimensional stability is difficult to ensure. And PA12 has the lowest water absorption rate of nylon products, this is due to the methylene molecules in nylon 12 greatly reduce the hydrophilic groups, which makes nylon 12 has a great advantage.

4) Impact strength

Impact strength is an important technical index, especially for nylon 12 pipe often exposed to air. Nylon 12 under -20℃ and -40℃ according to the standard test, no fracture phenomenon, fully meet the requirements of use. Nylon 12 has excellent impact resistance.

5) Low temperature performance

Nylon 12 has the lowest brittleness temperature of -70 degrees Celsius, so it can be widely used in low-temperature resistant parts. The following table lists the brittleness temperature of nylon resin:

6) Flexibility

The influence of plasticizer on the physical properties of nylon 12 is concentrated on the elastic modulus of resin. Nylon 12 has three basic types of resin, their main difference is due to the plasticizer content of different forms of flexibility. The elastic modulus of resin decreases with the increase of extractable component content of plasticizer.

7) Low wear and low friction performance

Nylon 12 has excellent low abrasion and low friction properties and self lubricating properties, so the friction noise of nylon 12 products is very low. The table below shows the values obtained for nylon 12 and other plastics by Tabor disk tests.

8) Fuel resistance

In automobiles, the mixture of oxygenated fuel, high aromatic fuel and alcohol currently used can cause the breakdown of many hose materials. After the test, only nylon 11, nylon 12 and fluorocarbon resin elastomers can be used in this environment. Almost other types of nylon melt under the action of automobile fuel, resulting in a change in size.

9) Resistance to zinc chloride solution

Zinc chloride is found under the car. Under certain temperature and humidity, the salt on the road reacts with galvanized steel plate or zinc-containing primer to form the corrosive zinc chloride. In addition, ozone aging, ultraviolet radiation, temperature conditions and so on, will bring different degrees of damage to the parts, reduce the service life.

Nylon 12 is very resistant to zinc chloride solution. Because there is no unsaturated double bond in nylon 12 which is susceptible to ozone attack, ozone aging does not occur. In addition, Nylon 12 UV resistance is also excellent.

10) Excellent electrical performance

The long carbon chain structure of nylon gives it excellent electrical properties. Because of the low water absorption of long carbon chain nylon, it still has excellent dielectric properties in the humid environment, which is not possessed by short carbon chain nylon such as nylon 6 and nylon 66.

Application

PA12 is the most widely used long carbon chain nylon. In addition to having most of the general properties of ordinary nylon, it has low water absorption, high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, the price of butadiene, the raw material of PA12, is only one third of the price of castor oil, the raw material of PA11. It can replace PA11 and be applied in most scenes, and has a wide range of applications in automobile fuel pipe, air brake hose, submarine cable, 3D printing and many other fields.

1. Automotive

Nylon 12 can be widely used in automotive fluid transmission lines, including fuel lines, clutch lines, vacuum brake supercharger lines, air brake lines, battery coolant lines and the joints of the above pipelines, because of its safety and reliability, is an excellent automotive lightweight material.

2. Pipe cables

Over the years, PA12 has been used in flexible risers, gas pipes, linings, and steel pipe coatings both onshore and offshore to protect against seawater erosion and oil fluid corrosion, flexible risers for the delivery of subsea oil and gas products and incoming fluids, and natural gas distribution systems at pressures up to 20bar. Nylon 12 has low embrittlement temperature and excellent weather resistance, especially suitable for the manufacture of field special purpose communication cables in all climates (-50 ~ 70℃).

3.3D printing

Compared with other materials, PA12 powder has excellent characteristics such as high fluidity, low static electricity, low water absorption, moderate melting point and high dimensional accuracy of products. The fatigue resistance and toughness can also meet the needs of higher mechanical properties of the workpiece, so nylon 12 gradually become the ideal material for 3D printing engineering plastics.

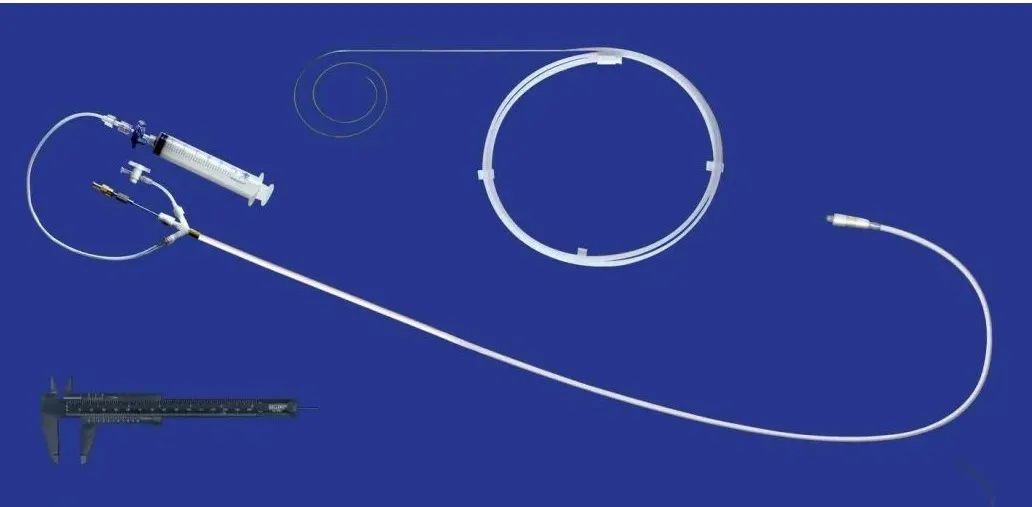

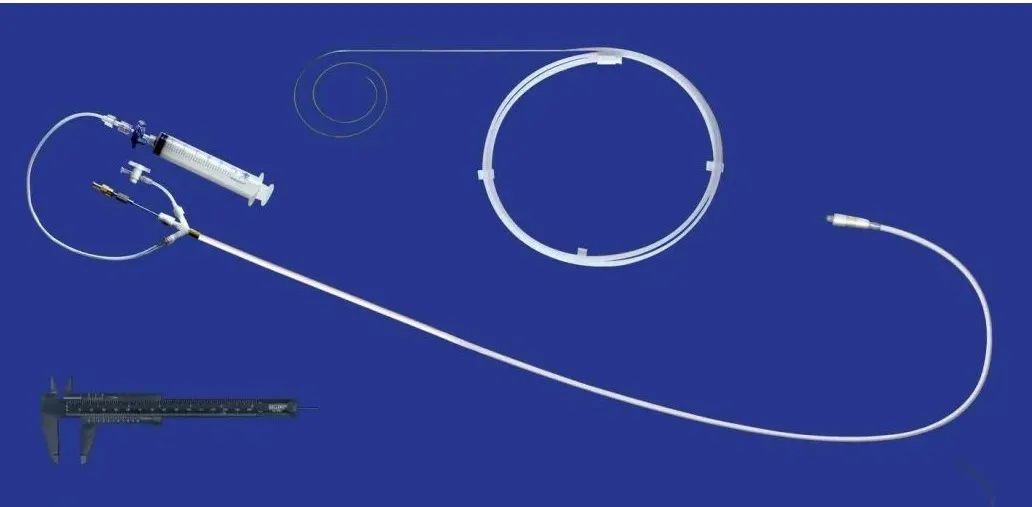

4.Medical care

PA12 is also used as a nursing medical material. The mechanical properties of the catheter material are particularly important. The catheter must be easy to thread, but not bend and never break. PA12 is an excellent material for catheter production due to its high bursting pressure, good flexibility, chemical resistance, compatibility with body fluids and non-toxic. It meets the requirements of the United States Food and Drug Administration and the European Union for medical products.

5. Daily necessities

PA12 excellent fatigue resistance, no spraying, can be used for glasses frames.

6. Recubrimientos y adhesivos avanzados

El nailon 12 se usa para recubrir el metal, la mejor resistencia a la fricción, por lo que a menudo se usa en la producción de recubrimientos y adhesivos avanzados. PA12 se puede usar en el soporte del tazón del nuevo lavavajillas para garantizar que el soporte del tazón de metal no se desgaste en el entorno del detergente a alta temperatura y que la vida útil sea más larga. También se puede aplicar a muebles de exterior, como bancos de parques, que pueden prevenir de manera efectiva la corrosión del metal después de recubrir con PA12.

proveedor de productos

Empresa compuesta de Xiamen LFT que se enfoca en LFT y LFRT. Serie de fibra de vidrio larga (LGF) y Serie de fibra de carbono larga (LCF). El termoplástico LFT de la compañía se puede usar para moldeo por inyección y extrusión LFT-G, y también se puede usar para moldeo LFT-D. Se puede producir de acuerdo con los requisitos del cliente: 5 ~ 25 mm de longitud.

Los termoplásticos reforzados con infiltración continua de fibra larga de la compañía han pasado la certificación del sistema ISO9001 y 16949, y los productos han obtenido muchas marcas comerciales y patentes nacionales.

correo electrónico

correo electrónico español

español English

English français

français Deutsch

Deutsch русский

русский italiano

italiano português

português العربية

العربية 日本語

日本語 한국의

한국의 中文

中文