Artículo No.:

MXD6-NA-LGF30Pago:

T/T or L/C (other payment ways also can be diorigen del producto:

Xiamen, ChinaColor:

Original color (also can be customized)Puerto de embarque:

Xiamen, ChinaMXD6 introducción

La polihexanodiil m-dimetilamina, conocida en inglés como mxd6, generalmente conocida como "nylon mxd6", la resina tiene mayor resistencia mecánica y módulo que otros plásticos de ingeniería, pero también un material especial de nailon de alta barrera.

Nylon mxd6 es uno de los miembros de poliacilo aromático y alifático, que es producido por m-fenilendimetilamina y ácido adípico.

En la producción industrial, para que las materias primas sean económicas y fáciles de obtener, a menudo se mezclan xilenos como materias primas, primero hechas de m-fenilendimetilamina con un contenido superior al 70% de benceno dimetilamina mixta, y luego con ácido adípico para generar sal, en presencia de una pequeña cantidad de ácido adípico estabilizador y una cantidad apropiada de agua para la reacción de condensación a presión, el polímero resultante es un híbrido.

Aunque la propiedad de barrera de mxd6 es un poco menor que la de pvdc y evoh, su propiedad de barrera no se ve afectada por la temperatura y la humedad, lo que es especialmente adecuado para ocasiones de alta temperatura y humedad. En los empaques de barrera de hoy y la tendencia general de reemplazar el acero con plástico, el nylon mxd6 se ha convertido en una de las nuevas variedades de plástico llamativas.

Ventajas

1, mantiene alta resistencia y rigidez en un amplio rango de temperatura

2, alta temperatura de deflexión térmica, pequeño coeficiente de expansión térmica

3, baja absorción de agua, pequeño cambio de tamaño después de la absorción de agua, menor reducción de la resistencia mecánica

4, pequeña tasa de contracción de moldeo, adecuada para procesos de moldeo de precisión

5、Excelente pintabilidad, especialmente adecuada para pintar superficies a altas temperaturas

6、Excelente barrera al oxígeno, dióxido de carbono y otros gases

Compuestos de fibra de vidrio larga

Long glass fiber reinforced composites can solve your problems when other methods of reinforced plastics do not provide the performance you need or if you want to replace metal with plastic. Long glass fiber reinforced composites can cost-effectively reduce the cost of goods and effectively improve the mechanical properties of engineering polymers, and increase the durability by forming long fibers to form a long-fiber-reinforced internal skeleton network.

Application

MXD6 can be filled with glass fibers to create a glass fiber reinforced material containing 20-60% glass fiber with exceptional strength and stiffness. Even when filled with high levels of glass fiber, its smooth, resin-rich surface creates a high gloss surface as without glass fiber, making it ideal for painting, metal coating or creating naturally reflective housings.

1、High fluidity for thin wall

It is a very high flowing resin that can easily fill thin walls as thin as 0.5 mm in thickness even when the glass fiber content is as high as 60%.

2、Excellent surface finish

The resin-rich perfect surface has a highly polished appearance, even with a high glass fiber content.

3、Very high strength and stiffness

With 50-60% glass fiber reinforcement, MXD6 has tensile and flexural strengths similar to many cast metals

and alloys.

4、Good dimensional stability

At ambient temperature, the coefficient of linear expansion (CLTE) of MXD6 glass fiber composite is similar to that of many cast metals and alloys. It is highly reproducible due to low shrinkage and the ability to maintain tight tolerances (length tolerances can be as low as ± 0.05% if properly formed).

MXD6 replaces metal in the production of high-quality structural parts for automobiles, electronics, and appliances

In automotive parts, many occasions require material products with high mechanical strength and good oil resistance, and can be used in the range of 120 ~ 160 ℃ for a long time. Glass fiber reinforced MXD6 has a heat resistance of up to 225°C and high strength retention at high temperatures, and can be used in cylinder blocks, cylinder heads, pistons, timing gears, etc. of automobile engines.

MXD6/PPO alloy has the properties of high temperature resistance, high strength, oil resistance, wear resistance, good dimensional stability, etc. It can be used for vertical outer panels of automobile bodies, front and rear fenders, wheel covers and curved parts that can hardly be formed by stamping with steel plates and automobile chassis.

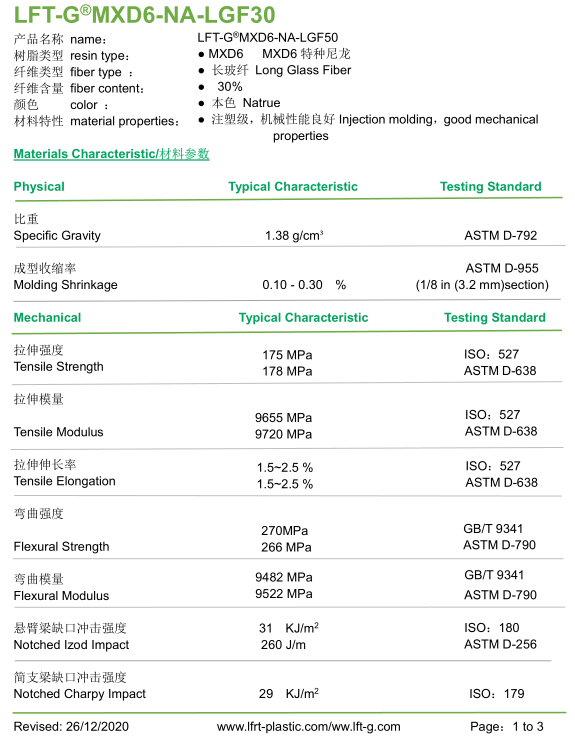

TDS foryour reference

Certifications

Quality Management System ISO9001/1949 Certification

National Laboratory Accreditation Certificate

Modified Plastics Innovation Enterprise

Honorary Certificate

Heavy metal REACH & ROHS testing

Xiamen LFT composite plastic Co., Ltd.

Xiamen LFT composite plastic Co., Ltd is a brand-name company that focuses on LFT&LFRT. Long Glass Fiber Series (LGF) & Long Carbon Fiber Series (LCF). The company's thermoplastic LFT can be used for LFT-G injection molding and extrusion, and can also be used for LFT-D molding. It can be produced according to customer requirements: 5~25mm in length. The company's continuous infiltration reinforced thermoplastics have passed ISO9001&16949 system certification, and the products have obtained lots of national trademarks and patents.