Categorías

nuevo blog

When you pick up your phone, take apart an auto part, or look at a home appliance casing, you might not realize that hidden inside these seemingly ordinary plastic products lies a kind of “invisible rebar” — glass fiber (GF). From PP + 20% GF to PA + 60% GF, these reinforcing fibers quietly support the plastic matrix, much like steel bars inside concrete.

Today, let’s uncover the mystery of long glass fibers, short glass fibers, and flat glass fibers, and see how they transform plastics into materials that achieve the perfect balance of strength and flexibility.

Glass Fiber: The “Reinforcement Code” of Plastics

What makes glass fiber the “golden partner” of engineering plastics lies in the fiber–resin synergy, which compensates for the inherent weaknesses of pure plastics:

1. Mechanical Reinforcement: Like adding a hidden skeleton to plastics, tensile strength can be improved by 20%–100%, while impact toughness can even approach the level of metals.

| Material |

Tensile Strength

|

Testing Standard

|

| Neat PP Resin | 30 MPa |

ASTM D-638

|

|

PP Short Glass Fiber Reinforced |

90 MPa |

ASTM D-638

|

| PP Long Glass Fiber Reinforced | 150 MPa |

ASTM D-638

|

The material data varies across different brands.

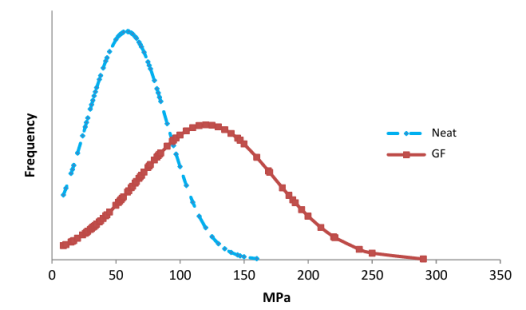

This chart compares the strength distribution of neat polymer (blue dashed line) and glass fiber reinforced polymer (red line). The neat polymer shows lower strength values concentrated around 70–90 MPa, while the glass fiber reinforced polymer exhibits a broader distribution with much higher strengths, extending up to around 300 MPa. This indicates that glass fiber reinforcement significantly improves the material’s mechanical performance.

2. Deformation resistance: suppresses resin shrinkage, making products less prone to warping under high temperature and stress, with a shrinkage rate controllable to as low as 0.15%.

3. Cost balancing: compared with pure engineering plastics, fiber-reinforced materials can achieve high performance at lower cost. For example, using long glass fiber PA to replace metal in automotive parts reduces weight by 58% while cutting costs by 30%. However, different forms of glass fiber bring very different “buffs” to plastics. The right choice can double product performance, while the wrong one may lead to issues such as fiber exposure and brittleness.

Type of fiber: long, short, or flat

The most commonly used glass fibers are long glass fiber, short glass fiber, and flat glass fiber. They differ significantly in morphology, performance, processing methods, and application scenarios, which is also reflected in their internal structural characteristics: